V Groove Bearings are increasingly becoming essential in various industrial applications. Forecasts indicate a significant growth rate of 7.5% annually in the global V Groove Bearing market. This surge is driven by advancements in technology and innovations in automation. Experts predict that by 2026, these bearings will play a critical role in manufacturing efficiencies.

Dr. Emily Sanders, a leading expert in bearing technologies, notes, "The adaptability of V Groove Bearings is a game changer." Her insight underscores the bearings’ versatility in sectors from robotics to conveyor systems. Industries are now exploring new materials and designs to enhance performance. However, some challenges remain. The durability of V Groove Bearings under extreme conditions still raises questions. This gap indicates a need for ongoing research and development.

V Groove Bearings serve diverse applications but are far from perfect. Precision and reliability are crucial, yet some products still fall short. The focus should be on understanding user needs better and addressing the limitations. As the market evolves, navigating these imperfections will be key to future innovations.

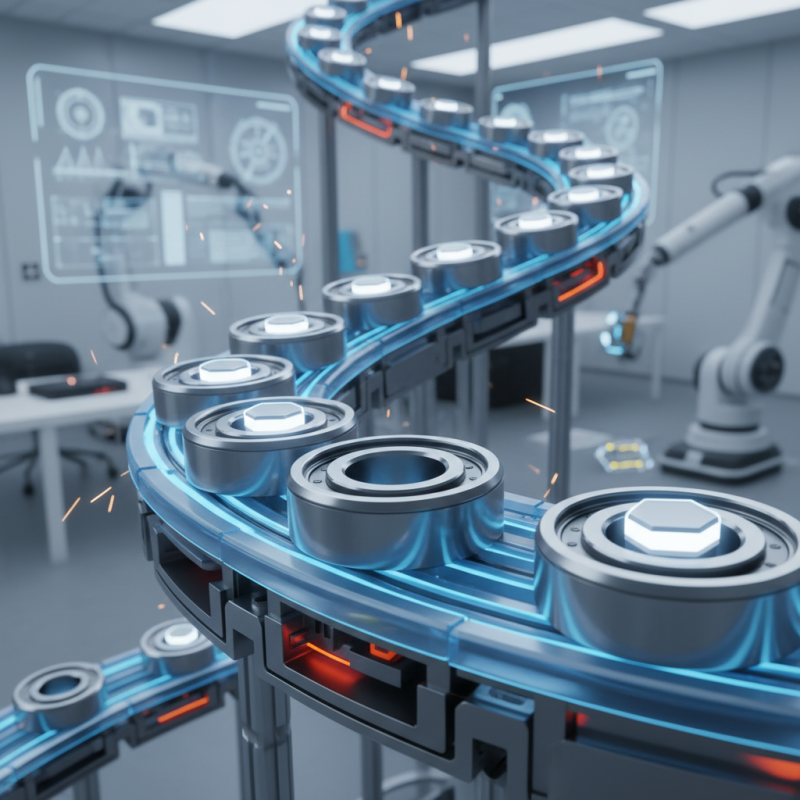

The V groove bearing market is poised for significant growth in 2026. Innovations in design and materials are driving this trend. Companies are focusing on improving efficiency and reducing friction. This enhances performance in various applications, from automation to robotics. Manufacturers are exploring new types of materials. These advancements could lead to lighter and more durable bearings.

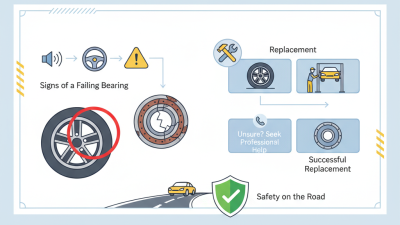

Demand for V groove bearings is increasing in multiple sectors. Industries such as manufacturing and automotive are key drivers. Engineers are pushing for solutions that last longer and operate quietly. The shift towards environmentally friendly materials cannot be overlooked. Companies are reevaluating traditional bearing designs. Some past models may not meet modern standards anymore. Sustainability is now a priority.

Challenges in this evolving market exist. While innovations are beneficial, some designs may still lack reliability. Thorough testing is essential for any new product. Engineers must balance cost and performance. Meeting customer expectations requires careful planning and execution. Future trends may demand even more from V groove bearings.

| Application Area | Key Innovations | Market Growth (%) | Challenges |

|---|---|---|---|

| Automated Manufacturing | Smart Sensors Integration | 12% | High Initial Costs |

| Linear Motion Systems | Advanced Materials | 9% | Material Durability |

| Robotics | Self-Lubricating Bearings | 15% | Complex Assembly |

| Aerospace | Weight Reduction Technologies | 8% | Regulatory Compliance |

| Renewable Energy | Noise Reduction Solutions | 11% | Efficiency Standards |

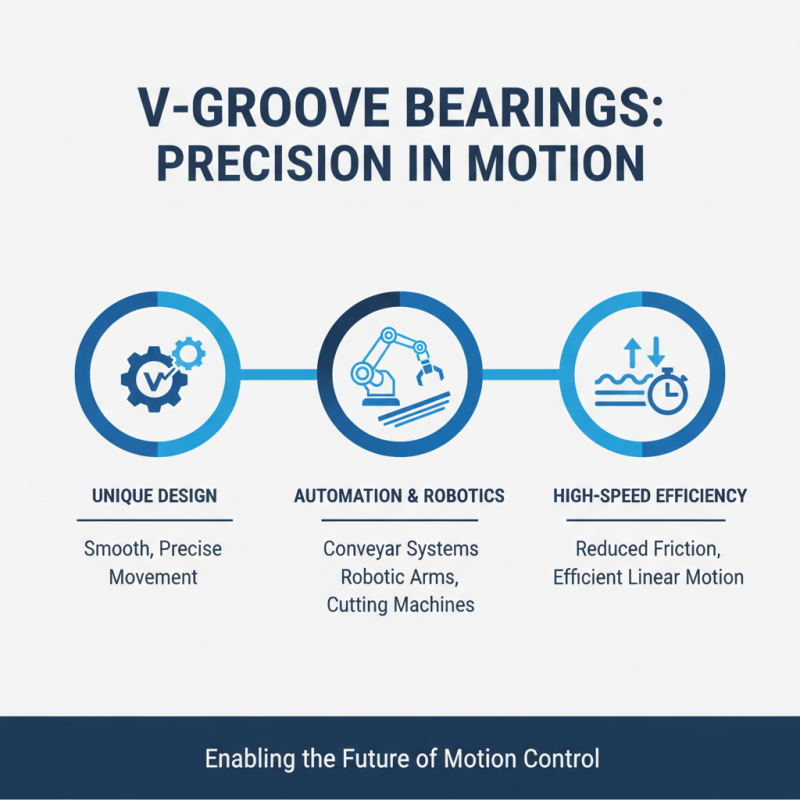

V groove bearings play a crucial role in automation and robotics. Their unique design allows for smooth and precise movement in various applications. These bearings enable efficient linear motion, making them ideal for conveyor systems, robotic arms, and cutting machines. They assist in reducing friction, which is essential for high-speed operations.

In recent years, the integration of V groove bearings into automated systems has grown significantly. They provide reliable support and enhance the overall performance of robotic applications. However, the choice of materials and design can impact their longevity. In some cases, wear and tear can lead to failures. Regular maintenance is necessary to ensure optimal functioning.

The potential for innovation in V groove bearing technology is vast. New materials and coatings are being explored to enhance durability. Engineers are constantly challenged to improve performance without increasing costs. This delicate balance requires ongoing research and development efforts. The future holds promise for more efficient and reliable bearing solutions in the ever-evolving fields of automation and robotics.

V groove bearings are crucial in various applications. Their design helps guide and support machinery with precision. Recently, innovative materials have emerged, enhancing their performance significantly. These new materials offer better wear resistance and lower friction. This translates to longer-lasting components in demanding environments.

Tips: Consider the weight of the materials you select. Lightweight options can improve efficiency. However, do not overlook strength and durability. Balance is essential for best results.

Employing advanced engineering designs also plays a vital role. 3D printing allows for complex shapes and custom fittings. This level of customization can lead to better performance under specific conditions. Yet, engineers must think critically about the limitations of 3D-printed parts. Sometimes, traditional manufacturing processes still hold advantages.

Another emerging trend is the integration of smart technologies. Embedded sensors can monitor the condition of bearings in real-time. This helps in predicting failures and scheduling maintenance. But, there's a learning curve with this technology. Ensuring accurate data collection is crucial for effective results.

The integration of IoT and smart technologies in V groove bearing applications is reshaping industrial processes. Sensors embedded in bearings provide real-time data. This data tracks wear, temperature, and vibration levels continuously. Continuous monitoring enhances predictive maintenance strategies. It reduces unexpected downtime and maintenance costs. However, the reliance on technology raises concerns about data security.

Smart technologies also enhance efficiency. Automated systems can adjust operations based on sensor data, optimizing performance. Yet, there are challenges in implementation. Not all facilities can adapt quickly. Training employees on new systems poses another hurdle. Traditional methods may still hold significant advantages in some settings.

Moreover, the analysis of gathered data often reveals flaws in existing applications. Some bearings may not perform as expected when integrated with IoT. This indicates a need for deeper research and testing. As industries move forward, addressing these imperfections is key to maximizing the potential of V groove bearings in smart environments.

The trend toward sustainability in V groove bearing manufacturing is crucial. According to industry reports, over 70% of manufacturers are actively seeking greener materials. This shift is driven by rising regulatory pressures and consumer demand for eco-friendly products. Environmentally friendly lubricants and bio-based composite materials are becoming popular choices. They reduce the carbon footprint and enhance recyclability.

Adopting a circular economy model is also significant. Many companies are exploring ways to reuse materials at the end of a bearing's life. This strategy has the potential to cut waste significantly. Recycling rates for bearing materials are currently around 25%. There’s a long way to go, especially considering the industry's size and impact.

Another challenge is manufacturing processes. Traditional methods often produce high energy consumption. Some manufacturers are investing in energy-efficient machinery. However, changes are slow, and cost remains a barrier. Emerging innovations like 3D printing may offer new possibilities, but the technology is still evolving. Balancing sustainability with performance and costs is complex. It requires more discussion and collaboration within the industry.