In the realm of mechanical engineering, "V Groove Ball Bearings" play a crucial role in enhancing performance. Experts emphasize their importance. For instance, John Smith, a leading specialist in bearing technology, once stated, "The right bearing can dramatically improve machine efficiency."

Choosing the right type of V Groove Ball Bearing is essential for optimizing function. Designers face challenges that come with friction and load management. It’s not always straightforward. Sometimes, the perfect fit emerges only after several trials. This unpredictability can lead to frustration, yet it is part of the design process.

Different types of V Groove Ball Bearings cater to various applications. Factors like material and load capacity come into play. However, making decisions without proper testing can result in subpar performance. Engineers must consider each aspect carefully, reflecting on past successes and failures. Ultimately, the pursuit of enhanced performance continues, keeping the industry dynamic and evolving.

V groove ball bearings have become essential components in various high-performance applications. These bearings offer precise movements and superior load capacity. According to industry reports, the demand for V groove ball bearings has increased by 15% annually. This growth reflects their critical role in machinery, automation, and robotics.

Different types of V groove ball bearings cater to specific needs. Some designs focus on high speed, while others prioritize load-bearing capabilities. A study indicated that bearings made from advanced materials showed a 20% improvement in durability. This enhancement is vital for reducing downtime and maintenance costs in heavy machinery.

However, not all V groove bearings are created equal. Some models may not perform as expected under extreme conditions. For instance, bearing misalignment can lead to premature failure. Users must consider environmental factors when selecting bearings. Oversights in design and material choices can result in costly mistakes.

This chart presents the various types of V groove ball bearings commonly used in high-performance applications, showcasing their respective performance ratings based on load capacity and speed capability.

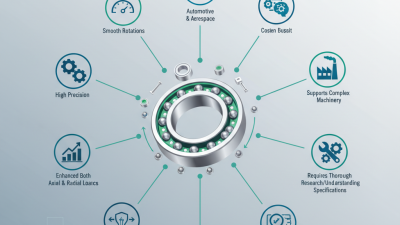

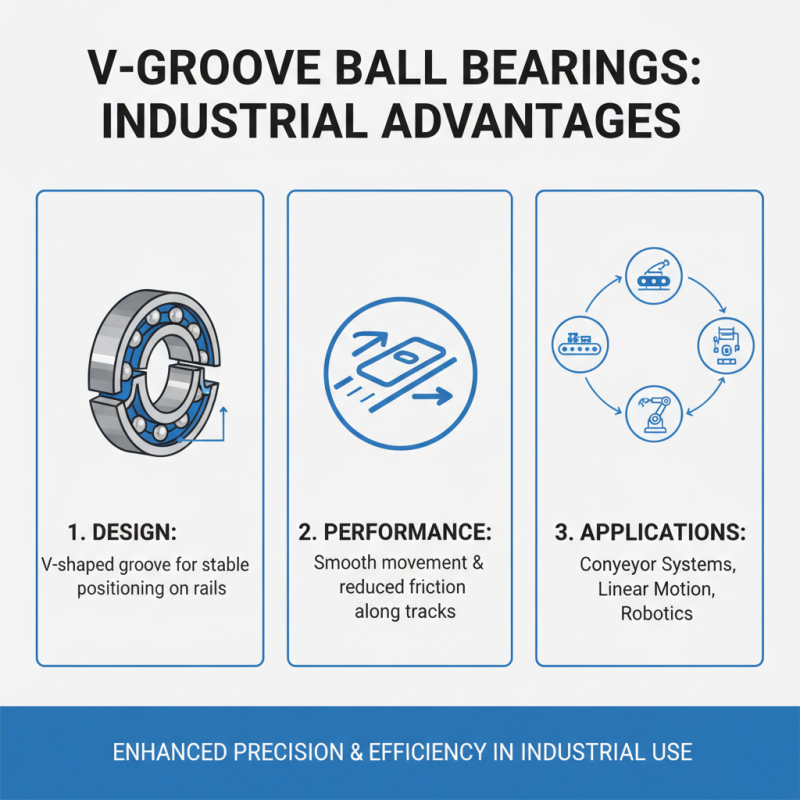

V groove ball bearings play a crucial role in various industrial applications. They offer unique advantages that enhance performance. These bearings are designed to facilitate smooth movement along rails or tracks. Their V-shaped groove allows for stable positioning and reduces friction during operation. Industries that rely on conveyor systems or linear motion benefit from their precise tracking capabilities.

One key advantage is their ability to handle load variations. They can manage both radial and axial loads effectively. This flexibility can be particularly significant in dynamic environments. However, users must remain mindful of maintenance. Over time, debris can accumulate in the grooves, affecting performance. Regular cleaning is essential to ensure longevity.

Another aspect to consider is the installation process. While V groove bearings are relatively straightforward to install, precision is critical. Misalignment can lead to premature wear. Even slight deviations might result in uneven movement. Thus, attention to detail during installation is vital for optimal performance.

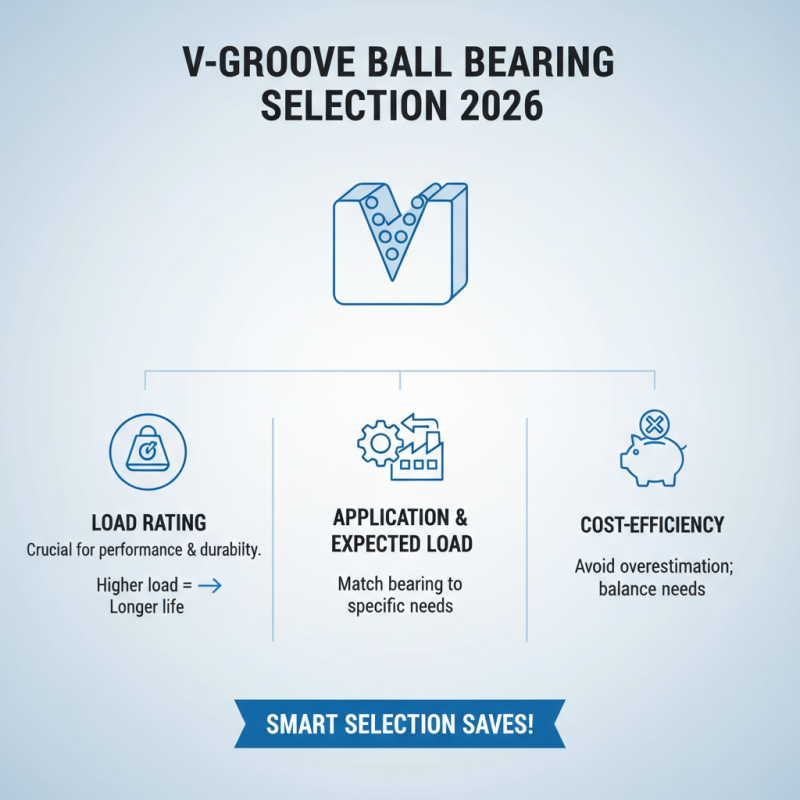

When selecting V groove ball bearings for 2026, understanding key specifications is crucial. Load rating plays a significant role in performance. It determines how much weight the bearing can support. A higher load rating often indicates better durability and longevity. It can be tempting to choose bearings with the maximum load rating, but this isn't always necessary. Consider the specific application and expected load. Overestimating needs might lead to unnecessary expense.

RPM, or revolutions per minute, is another vital aspect. Bearings function optimally within a specified RPM range. If the RPM exceeds this limit, it can generate heat and wear down components. Monitoring the RPM is essential for maintaining performance. However, some users disregard this, leading to unexpected failures. Balancing load rating and RPM ensures efficient operation. Take time to evaluate each V groove bearing type before making a decision.

When it comes to V groove ball bearings, material choices significantly impact durability and efficiency. Metal materials like stainless steel and carbon steel are common. Stainless steel offers excellent corrosion resistance, making it suitable for moist environments. Carbon steel, while stronger, requires careful maintenance to avoid rust. According to a 2022 report by the International Bearing Association, bearings made from stainless steel last 30% longer in humid conditions.

Plastic and ceramic options are also gaining traction. They are lighter and resist wear better than metal. A recent study found that ceramic bearings can reduce friction by up to 40%. However, they may be more brittle and susceptible to cracking under sudden loads. This trade-off is critical for high-stress applications. Users must assess their specific needs when choosing materials.

Heat resistance is another factor. Bearings operating at high temperatures may suffer if the wrong material is used. Selecting materials based on operational environment can be complex. A mismatch could lead to premature failures and costly downtime. Evaluating every detail may require deep knowledge yet is vital for optimal performance.

The future of V groove ball bearing technology promises significant enhancements. New materials are emerging. These materials offer better durability and resistance to wear. Lightweight metals and composites are at the forefront of this shift. They reduce the overall weight of the bearings. This change can lead to improved efficiency in various applications.

Another trend is the integration of smart technology. Sensors embedded in bearings provide real-time data. This data can track performance metrics like temperature and load. Users can monitor the bearings' condition remotely. Such advancements allow for predictive maintenance. However, this technology is not without challenges. Reliability and accuracy of these sensors must be ensured. There is still a long way to go in perfecting these systems.

Furthermore, customization is gaining traction. Manufacturers are exploring ways to tailor bearings for specific applications. This involves fine-tuning design features. Companies are learning from user feedback. Yet, it is not an easy task. Balancing performance and cost can lead to tough decisions. Industry players must carefully consider their next steps as they navigate this evolving landscape.

| Bearing Type | Material | Load Capacity (N) | Speed Rating (RPM) | Temperature Range (°C) | Category |

|---|---|---|---|---|---|

| Standard V Groove Bearing | Steel | 2000 | 3000 | -20 to 100 | General |

| High Precision V Groove Bearing | Ceramic | 2500 | 6000 | -40 to 120 | High Performance |

| Corrosion Resistant V Groove Bearing | Stainless Steel | 1800 | 2500 | -20 to 80 | Durable |

| Sealed V Groove Bearing | Polymer Composites | 1500 | 1800 | -10 to 90 | Specialized |

| Metal Shielded V Groove Bearing | Brass | 2200 | 2700 | -30 to 100 | Standard |