Angular ball bearings are increasingly vital in modern technology. Their design allows for high precision and smooth rotations. Industries ranging from automotive to aerospace benefit significantly from their use.

These bearings can handle both axial and radial loads effectively. As machinery becomes more intricate, angular ball bearings provide essential support. They enhance equipment performance, but users must remain cautious of maintenance needs.

Choosing the right angular ball bearing requires thorough research. Some users overlook size and load ratings, leading to failures. Understanding specifications is crucial for optimal operation. As manufacturers innovate, staying informed about options will ensure the best choices for modern applications.

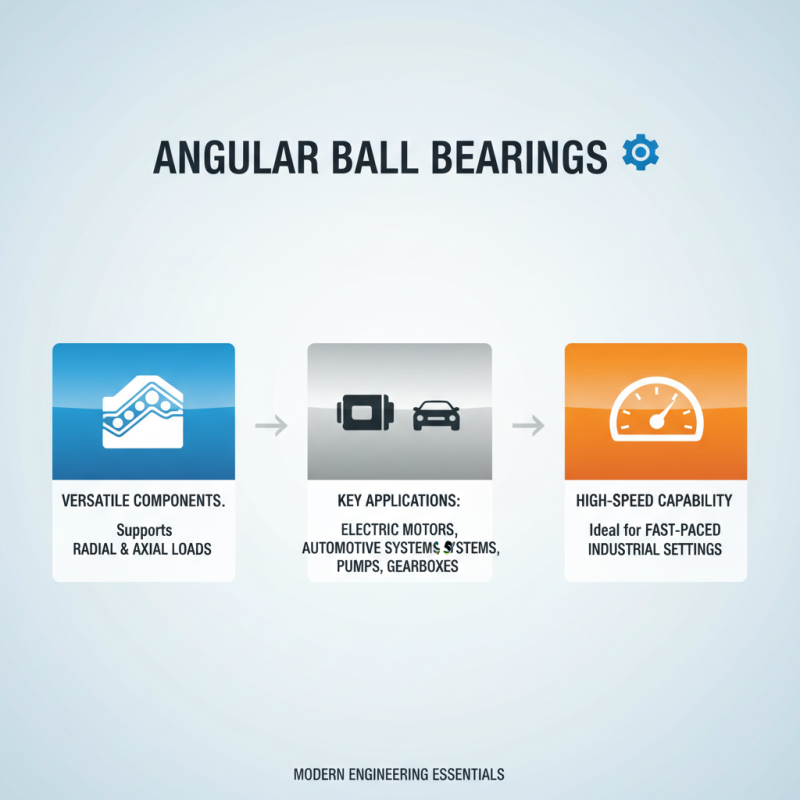

Angular ball bearings are essential components in modern engineering. They are designed to support both radial and axial loads, making them highly versatile. This unique capability allows them to operate effectively in various applications, from electric motors to automotive systems. Their ability to handle high speeds adds to their appeal in fast-paced industrial settings.

These bearings have a distinct shape, featuring an inner and outer raceway at an angle. This design helps distribute forces more evenly. In practice, this means they can manage heavier loads compared to standard ball bearings. However, they require precise alignment during installation. A slight misalignment can lead to premature wear.

Another important aspect is lubrication. Angular ball bearings benefit from proper grease or oil application for optimal performance. Insufficient lubrication may cause overheating and failure, leading to costly downtime. Engineers must prioritize maintenance to ensure longevity in applications. The balance between efficiency and care cannot be overlooked.

Angular ball bearings play a crucial role in modern machinery. They excel in load distribution, especially in rotating applications. This design allows for better handling of both radial and axial loads. Improved weight distribution minimizes wear and tear. As components rotate, angular bearings maintain stability. This results in enhanced performance and longevity.

When selecting angular ball bearings, consider the load rating. Make sure it matches your application needs. Inspect the fit with housing. A proper fit ensures smooth operation. Misalignment can lead to reduced efficiency.

Regular maintenance is key. Check for signs of wear. Ensure lubrication is adequate. Neglecting these tasks can result in failure. Sometimes, engineers overlook the importance of these checks. A small oversight can lead to significant issues later on. Prioritize these aspects for optimal performance.

The use of angular ball bearings significantly elevates the performance of high-speed machinery. These bearings allow for superior load distribution, which is crucial in fast-moving applications. They often reduce friction, improving efficiency. The design of angular ball bearings reduces the heat generated during operation, enhancing overall durability.

In high-speed environments, precision is essential. Slight misalignments can cause failures. Angular ball bearings are designed to maintain alignment under stress. This adherence helps minimize wear over time, but it is not foolproof. Regular inspection is still necessary to identify potential issues early.

Using angular ball bearings can lead to smoother operation and increased speed. However, they also require careful handling and appropriate installation. When mismanaged, they may lead to unexpected downtimes. It's essential to understand their limits and performance specifications fully. Regular monitoring can ensure they continue to function at peak efficiency.

Angular ball bearings are pivotal in reducing friction and wear, leading to substantial longevity in various applications. According to industry reports, friction can account for up to 60% of energy loss in machinery. Minimizing this friction is vital, especially in high-performance environments. Angular ball bearings achieve this by allowing for greater load distribution while facilitating smoother rotational movement.

The materials used in these bearings also play a significant role. High-quality steel or ceramic balls decrease wear effectively. Data reveals that advanced materials can increase bearing lifespan by up to 30%. However, even with these materials, improper installation can lead to premature failure. Regular maintenance is crucial as debris and contamination can also decrease efficiency.

Despite their numerous advantages, they are not without challenges. For instance, they can be sensitive to misalignment and require precise tolerances. The initial costs may be higher compared to plain bearings. Understanding these nuances is essential for optimizing performance and ensuring long-term reliability in applications ranging from automotive to aerospace industries.

Angular ball bearings are increasingly popular across various industrial sectors. Their unique design allows them to manage both axial and radial loads. This versatility is crucial for applications in automotive, aerospace, and manufacturing. For example, in automotive systems, these bearings help reduce friction, improving fuel efficiency and performance. They also play a vital role in electric motors, where smooth operation is essential.

Consider the use of angular ball bearings in robotics. They contribute to precise movements and enhanced durability. This reliability makes them ideal for high-speed applications. However, it’s important to choose the right type based on load requirements and environmental conditions.

Tip: Regularly inspect and maintain bearings to ensure optimal performance. Overlooking small signs of wear could lead to greater issues down the line. Remember that not all applications require the same specifications; adjust accordingly. In some cases, limitations emerge when dealing with heavier loads or harsh environments. Choosing a suitable bearing type is essential to prevent breakdowns and enhance efficiency.