In 2026, the quest for optimal performance in machinery heavily revolves around Ball Bearings. The bearing industry is projected to grow significantly, with a compound annual growth rate (CAGR) of 6.2% from 2021 to 2026, according to a recent market report. This growth underscores the importance of selecting the right type of Ball Bearings for various applications.

Bearings Ball serve a critical role in reducing friction and wear in many mechanical systems. Various types, such as deep groove, angular contact, and self-aligning bearings, each have unique characteristics. For instance, deep groove bearings are prized for their versatility, while angular contact bearings excel in high-speed applications.

However, challenges remain. Not all Ball Bearings deliver the expected durability. This leads to increased operational costs and maintenance concerns. Quality control and material selection are crucial areas needing reflection. Industry stakeholders must prioritize innovation to improve bearing performance. As we explore the best types of Ball Bearings in 2026, understanding their potential and limitations is vital for future advancements.

Ball bearings are crucial components in many machines. They reduce friction between moving parts. This leads to smoother operation and greater efficiency. By allowing parts to rotate freely, ball bearings improve performance in applications ranging from engines to household appliances.

Tips: Regular maintenance is key. Check bearings for wear and tear often. Early detection can save costs and time.

Upon exploring different types, it's clear that specific designs suit different needs. Some environments may require durable materials. Others thrive on precision design. Mistakes often arise from choosing the wrong type for the application. Reflect on how critical the right bearings are to your machinery.

Tips: When selecting ball bearings, consider the environment they're in. Moisture, temperature, and load factors all matter. Proper selection enhances lifespan and performance.

| Bearing Type | Material | Load Capacity (kg) | Speed Rating (RPM) | Typical Applications |

|---|---|---|---|---|

| Deep Groove Ball Bearing | Steel | 400 | 5000 | Electric Motors, Fans |

| Angular Contact Ball Bearing | Ceramic | 600 | 8000 | Spindles, Pumps |

| Thrust Ball Bearing | Stainless Steel | 300 | 3000 | Gearbox, Lift Systems |

| Self-Aligning Ball Bearing | Polymer | 250 | 4500 | Textile Machinery, Conveyors |

| Spherical Roller Bearing | Bronze | 800 | 3500 | Construction Equipment, Mining |

In 2026, the landscape of ball bearings is evolving. A comparative analysis reveals various types designed for different applications. Deep groove ball bearings remain popular due to their versatility. They handle radial and axial loads effectively. These bearings are commonly used in motors and automotive applications, where reliability is critical.

Angular contact ball bearings are another strong contender. They excel in high-speed applications, offering better performance under axial loads. According to recent industry reports, mechanical failures in high-speed machinery often relate to inadequate bearing selection. Many engineers overlook the significance of choosing the right type, leading to costly downtime.

Thrust ball bearings serve a specific need. They support axial loads well, which is crucial in applications like cranes or screw jacks. However, they may falter under radial loads, leading to potential failures. Designers must reflect on their choices carefully. Each bearing type has unique advantages and disadvantages. Balancing these characteristics is essential for optimal performance.

When selecting ball bearings, several factors significantly influence their performance. The material used plays a crucial role. Steel and ceramic bearings have different properties that affect durability and friction. For instance, ceramic bearings are lighter and resist corrosion. However, they can be more brittle than steel.

Notably, lubrication is a key consideration. Proper lubrication minimizes friction and wear. Using the right lubricant increases efficiency. Research indicates that up to 50% of bearing failures result from inadequate lubrication. This highlights the importance of regular maintenance and proper lubricant types.

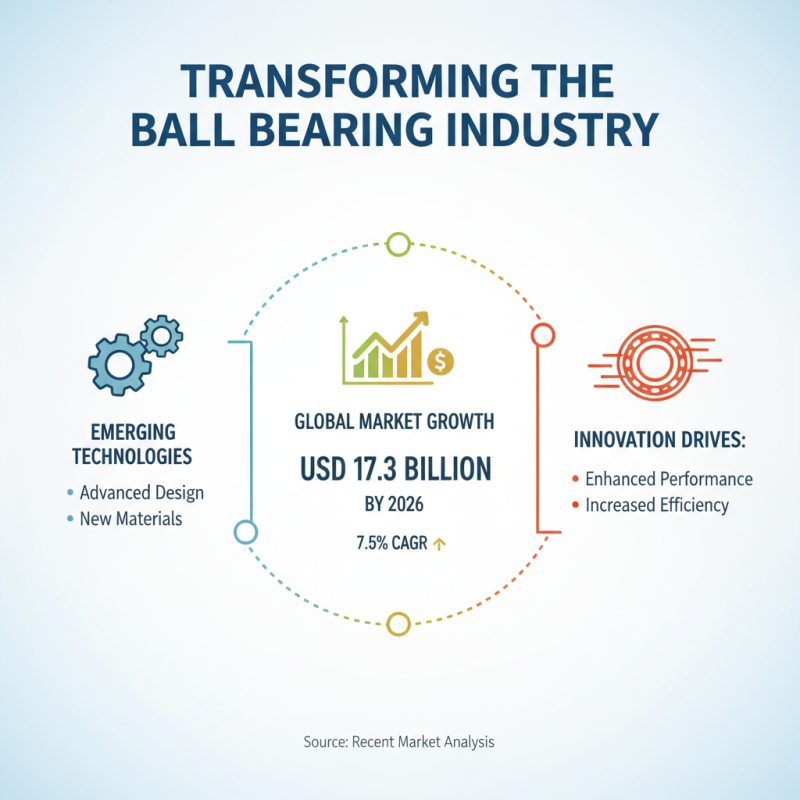

The ball bearing industry is experiencing transformative changes. Emerging technologies in design and materials are driving significant advancements. According to a recent market analysis, the global ball bearing market is set to reach $17.3 billion by 2026, reflecting a compound annual growth rate of 7.5%. This growth is fueled by innovations that enhance performance and efficiency.

One noteworthy development is the adoption of ceramic materials in ball bearings. Ceramics offer lower friction and higher resistance to wear compared to traditional steel. Reports indicate that bearings made from advanced ceramics can last up to three times longer than conventional options. This presents an opportunity but also requires further exploration into manufacturing methods to optimize processes.

Another area of focus is smart bearings, integrating IoT technology for real-time monitoring. These intelligent systems can predict failures and reduce downtime. Nonetheless, the adoption of such technologies raises concerns. What about compatibility with existing systems? How do we ensure data security? These questions highlight the need for a careful approach as the industry moves forward. The potential is vast, yet execution remains a challenge.

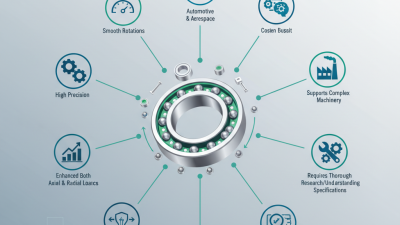

Ball bearings are essential components in many industries. Their applications range from automotive to aerospace, making them crucial for operational efficiency. In 2026, ball bearings will continue to evolve, adapting to the increasing demands of various sectors. Reports indicate that the global ball bearing market is expected to reach $50 billion by 2027, driven by technological advancements and increasing industrialization.

In manufacturing, ball bearings play a vital role in machinery to reduce friction. They enable smooth operation, leading to less wear and tear. This not only improves efficiency but also extends equipment life. A study by the American Society of Mechanical Engineers revealed that improperly selected bearings can lead to a 30% reduction in machinery lifespan, highlighting the importance of choosing the right type.

Tip: Always assess operating conditions before selecting ball bearings. Consider factors like load, speed, and environmental conditions. This will optimize efficiency and performance.

In the aerospace industry, ball bearings are integral to engine performance and control systems. The need for precision and reliability is paramount. A failure here can lead to significant consequences. Engineers must continuously evaluate the suitability of bearing materials and designs. Oftentimes, overlooked factors can lead to unexpected failures, emphasizing the need for thorough testing and validation.

Tip: Keep an eye on the latest industry reports. They provide valuable insight into emerging trends and innovations in ball bearing technology.