The world of Bearing Roller Cylindrical technology is constantly evolving. Industry expert James H. Lewis emphasizes, "Choosing the right type affects performance significantly." This statement highlights the importance of making informed decisions in this field.

As businesses seek efficiency, understanding the different types of Bearing Roller Cylindrical options becomes essential. These components play a crucial role in various industries, from automotive to aerospace. Selecting the right bearing can improve machinery performance and extend service life.

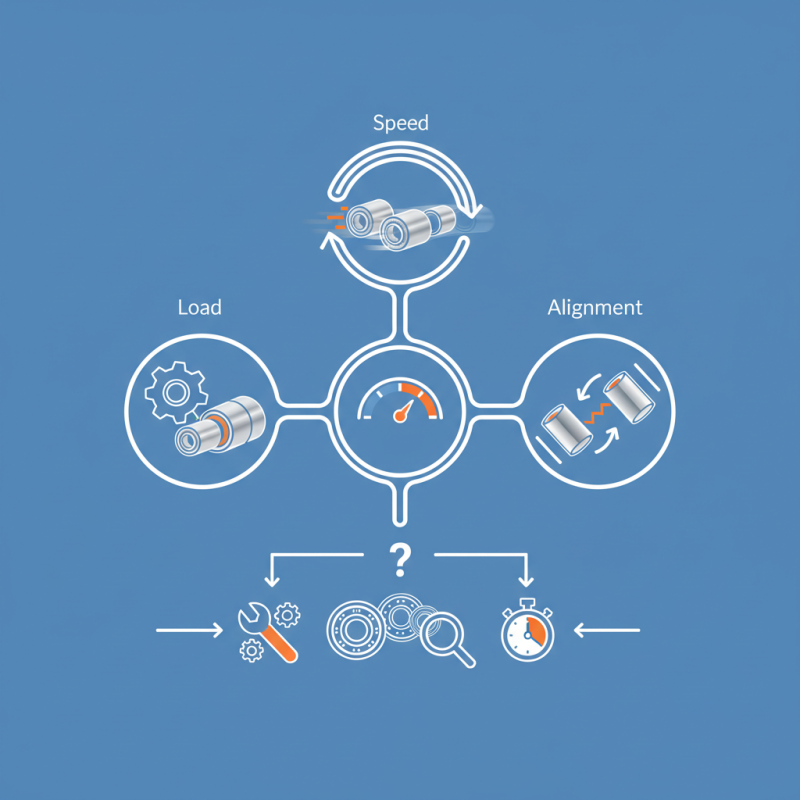

However, not every option is suitable for every application. Engineers must weigh factors such as load, speed, and alignment. Often, trial and error is involved in determining the best choice. These challenges highlight the need for continual learning in the Bearing Roller Cylindrical sector.

As we look towards 2026, the landscape of bearing roller cylindrical types is evolving. Many industries are embracing innovative materials. These advancements promise better performance and durability. For instance, synthetic materials are becoming popular. They can withstand higher temperatures and pressures. This change may lead to longer equipment life.

The trend of lightweight design is also significant. Reducing weight can enhance efficiency. In many applications, every gram counts. Yet, there's a challenge. Moving to lighter materials might compromise strength. Manufacturers must find a balance.

Additionally, digital technologies are influencing this sector. Sensors embedded in bearings can monitor performance. This data helps in predictive maintenance, reducing downtime.

However, the move toward automation raises questions. How will it affect manufacturing processes? Human oversight remains essential. The shift may improve precision, but it also requires skilled workers. Therefore, as we explore these trends, reflection is necessary. The future landscape may promise advancements, but challenges will always remain.

Cylindrical roller bearings are crucial in many machinery applications. They are known for their high load capacity and efficient performance. However, not all cylindrical roller bearings are created equal. Each type has unique features that can affect overall performance.

When comparing different types, focus on their structure. Some have inner and outer rings designed for axial load, while others may have a higher number of rollers for better load distribution. The materials used also play a role. Steel or ceramic options have distinct advantages and drawbacks. While steel is more durable, ceramic might offer better resistance to wear and temperature variations.

Performance can vary based on lubrication types as well. Some bearings thrive in grease, while others perform better in oil. The environment matters, too. High humidity or extreme temperatures can lead to unexpected failures. Regular checks are essential, yet often overlooked. Understanding these challenges is vital for optimizing functionality.

This chart illustrates the load capacity of different types of cylindrical roller bearings. The data highlights the comparative performance of Type A through Type E with respect to their load carrying capabilities measured in kilonewtons (kN).

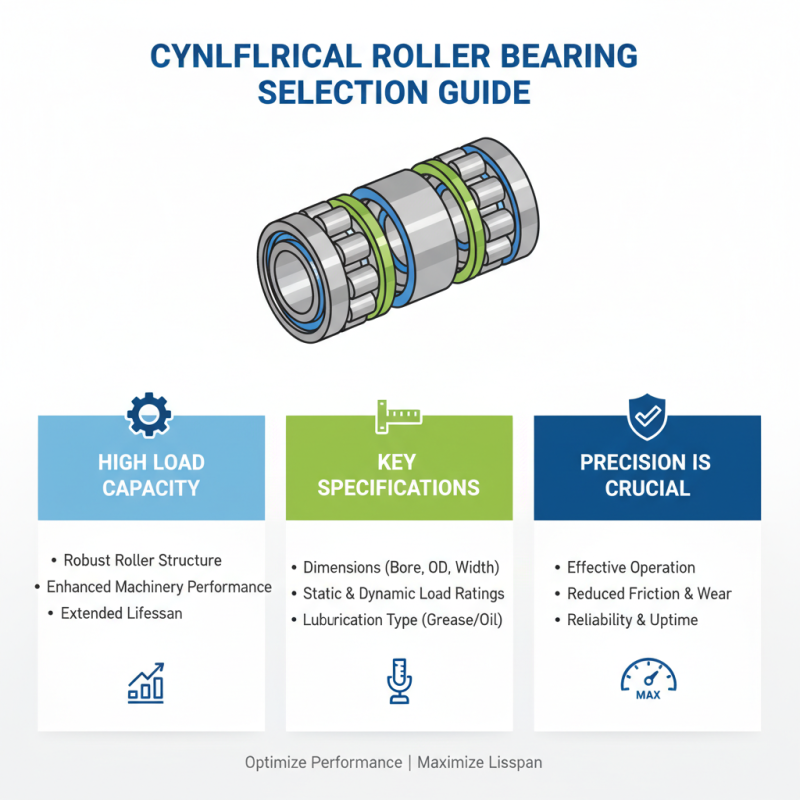

When selecting cylindrical roller bearings, various specifications and features play a crucial role. The structure of the roller is typically designed for high load capacity. This enhances the performance and lifespan of machinery. Key specifications often include dimensions, load ratings, and lubrication types. Precision in these areas is essential for effective operation.

Moreover, the material composition matters significantly. High-quality steel or composite materials can improve durability. Yet, not all materials perform equally under various conditions. Corrosion resistance and heat tolerance should also be considered. These elements directly affect how long the components last in extreme environments.

Another factor to reflect on is the design of the cages. Some designs allow for better lubrication flow and reduced friction. This leads to improved efficiency. However, the right choice may depend on the specific application. Each option has its pros and cons. Assessing these attributes can be challenging. It's imperative to weigh them according to your distinct requirements.

In 2026, the market for cylindrical roller bearings is expected to see significant growth. According to recent projections, demand may increase by around 7.5% annually. This surge is attributed to rising automation and industrial processes. Applications in automotive and aerospace are driving this trend. Manufacturers seek efficient solutions to enhance performance and reduce downtime.

Cylindrical roller bearings excel in handling radial loads. Their design allows for higher load capacities and greater stability. This is crucial in industries that demand precision and reliability. The overall increase in machinery production will further amplify demand for these bearings.

Tip: Regular maintenance is key. A small oversight can lead to significant issues down the line. Monitor bearing temperature and vibration levels. This can prevent unexpected failures and costly repairs.

While the growth potential seems promising, challenges persist. Quality control remains a constant concern. Fluctuations in material prices may affect production costs. It’s essential for companies to invest in technology to ensure consistent quality. Adapting to changing regulations will also be crucial for survival.

In recent years, material science has revolutionized bearing performance. Innovations are enhancing durability and efficiency. Advanced materials like ceramics and composites offer unique benefits. They resist wear and reduce friction, leading to longer lifespan. Manufacturers are experimenting with hybrid materials. These combine the strength of metals with the lightweight properties of plastics.

Tips for implementing these innovations include selecting the right material based on application. Consider the environment where the bearing will operate. High temperatures or corrosive substances can affect performance. Research is crucial in making informed decisions. Pay attention to the load capacity and speed requirements of your machinery.

Replacing traditional materials with innovative options may not always guarantee better performance. Testing is vital to ensure the new material meets your needs. Sometimes, what works for one application may not work for another. Regular evaluations will help identify any shortcomings. Balancing cost and performance can lead to complicated decisions. Look closely at how these materials interact with your machinery.

| Type | Material | Load Capacity (kN) | Speed Rating (RPM) | Temperature Range (°C) | Application |

|---|---|---|---|---|---|

| Cylindrical Roller Bearing | Steel | 100 | 3000 | -20 to 120 | Automotive |

| Tapered Roller Bearing | Alloy Steel | 150 | 2500 | -30 to 150 | Industrial Machinery |

| Spherical Roller Bearing | Stainless Steel | 160 | 2000 | -40 to 180 | Heavy Equipment |

| Needle Roller Bearing | Polymer | 80 | 4000 | -20 to 100 | Robotics |

| Cylindrical Roller Thrust Bearing | Bronze | 120 | 1500 | -10 to 140 | Marine Applications |