In the realm of industrial applications, "Steel Ball Bearings" are pivotal for enhancing performance and durability. According to a recent report by MarketsandMarkets, the global ball bearing market is expected to reach $119.6 billion by 2025, driven by the increasing demand in automotive and manufacturing sectors. The durability of these bearings directly influences machinery efficiency.

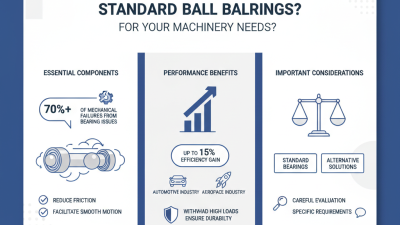

Choosing the right steel ball bearings can significantly impact operational costs. For instance, quality bearings can reduce friction and wear, leading to longer equipment lifespans. These bearings are essential in applications ranging from electric motors to aerospace components. An investment in high-performance bearings often yields better returns over time.

However, not all steel ball bearings are created equal. Variability in material quality, manufacturing processes, and design can lead to performance issues. Companies sometimes overlook these factors, leading to failures in critical systems. Identifying the ideal bearing requires careful consideration and expert insight, especially in high-stakes industries where reliability is non-negotiable.

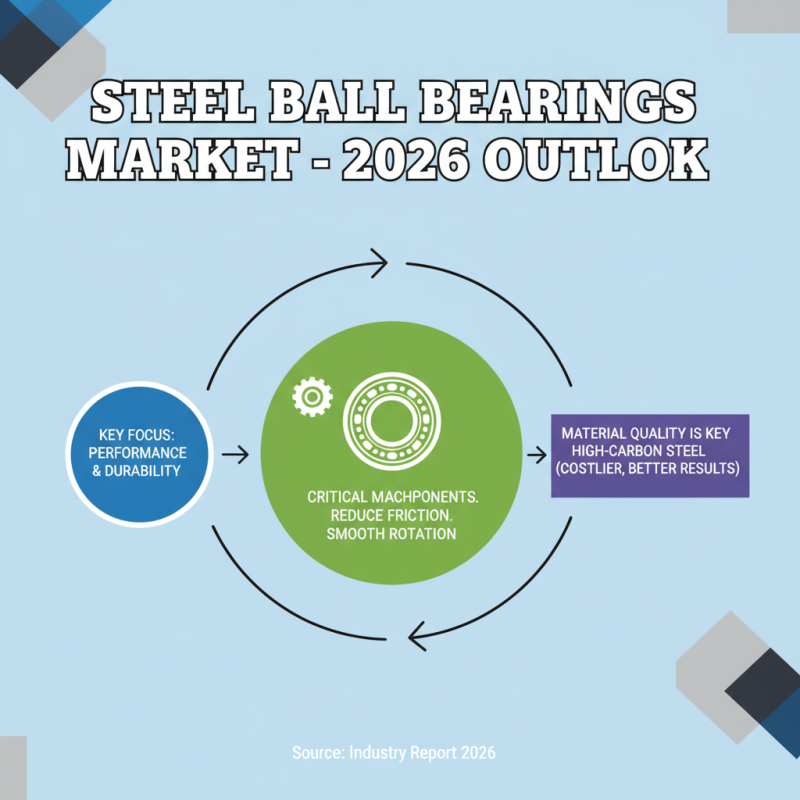

In 2026, the market for steel ball bearings focuses heavily on performance and durability. These components play a critical role in machinery. Steel ball bearings ensure smooth rotation and reduce friction. When selecting them, material quality is key. High-carbon steel often yields better results, but it can be costlier.

However, the journey to find the best often reveals imperfections. Some high-performance options may wear faster under heavy loads. Durability may vary based on the environment. Humidity and temperature fluctuations can affect their lifespan. Regular maintenance is necessary for optimal function. Neglecting this can lead to premature failure and costly repairs.

In conclusion, understanding the balance between performance and durability is crucial. Users often overlook the importance of specifications. They may choose based on short-term gains rather than long-term benefits. This can lead to disappointment. Investing time in research pays off. A careful selection can improve both performance and longevity significantly.

When selecting steel ball bearings, several key features should be at the forefront of your considerations. Material quality is crucial. High-grade steel ensures durability and performance. Look for bearings that avoid corrosion. This can be essential for longevity. Additionally, check the bearing’s load capacity. This will determine how much weight the bearing can handle efficiently.

Another vital feature is the bearing’s precision. Precision refers to how well the bearing can operate under various conditions. Higher precision often means better performance. Be mindful of the type of lubrication used. Proper lubrication can significantly affect the lifespan of the bearings. Using the wrong lubricant can lead to premature wear and failure.

Tips: Always inspect for any signs of wear. Small scratches can indicate problems. Consider the operating environment. Will it face dust or moisture? Choose bearings designed for such conditions. Also, think about maintenance. Some designs are easier to maintain than others. Don't overlook these factors; they could save you trouble in the long run.

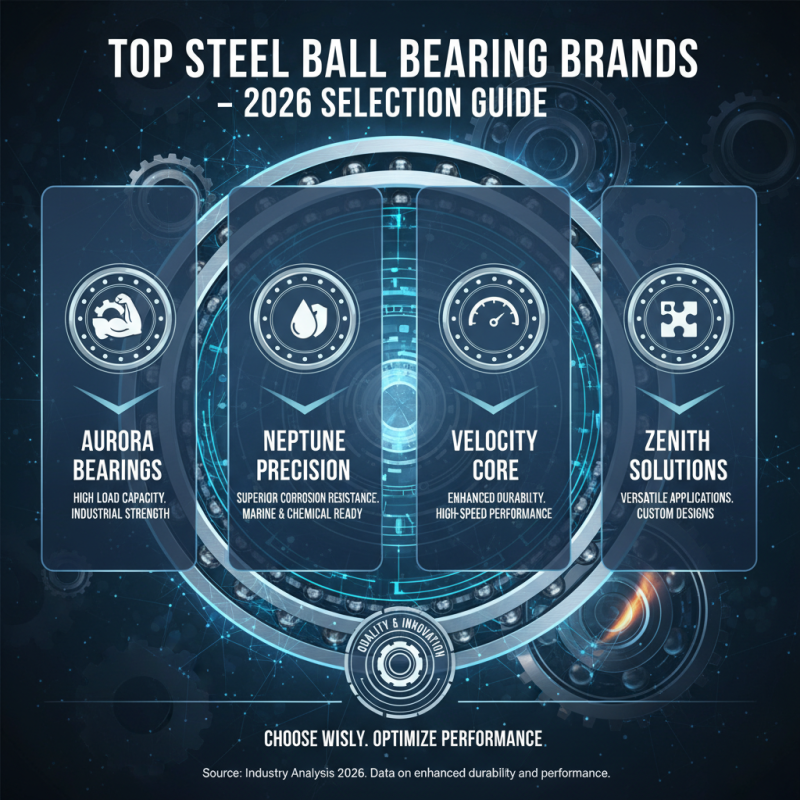

When choosing the best steel ball bearings in 2026, it's crucial to consider the top brands and manufacturers known for their quality. Many companies today focus on enhancing durability and performance. Each brand has unique features that cater to different needs. Some prioritize high load capacity, while others offer superior corrosion resistance.

When selecting ball bearings, consider the material choice. The best steel compositions ensure longevity and lower friction. Additionally, check the tolerance levels. Higher precision leads to better performance. Don't overlook the importance of seals and shields. They protect bearings from dust and contaminants, prolonging their life.

Tip: Always compare specifications. Each manufacturer may have different metrics for load and speed ratings. Read reviews and ask for recommendations when in doubt. Reflect on your specific application. What works for one project might not suit another. Pay attention to the long-term costs versus initial prices.

When comparing steel ball bearings, performance ratings reveal much about their suitability for various applications. These bearings often come in different sizes and materials, directly affecting their efficiency. A higher-performance rating typically indicates better speed, stability, and load-bearing capacity. Reviews from users provide valuable insights into real-world performance, although experiences may vary.

Many users have noted the importance of proper lubrication. It can drastically influence the lifespan of the bearings. A well-lubricated bearing operates smoother and quieter. On the other hand, inadequate lubrication can lead to wear and tear. This is often overlooked in user feedback, so it's essential to consider.

Tip: Regular maintenance checks can prevent significant issues down the line. Testing your bearings periodically can help you catch problems early. Keep an eye on wear patterns and listen for unusual noises. This awareness can save you time and money. Remember, not all bearings are made equal. Look for detailed reviews to make an informed decision.

Steel ball bearings are essential components in various applications, from industrial machinery to consumer electronics. Their design influences performance and durability. A quality steel ball bearing can enhance efficiency significantly. For instance, using high-grade stainless steel can increase resistance to corrosion, which is crucial in harsh environments. The National Lubricating Grease Institute reports that proper lubrication can boost bearing life by up to 50%. However, selecting the right bearing for your application requires careful consideration.

Industries like automotive and aerospace demand precision. Ball bearings help reduce friction, which enhances fuel efficiency and overall performance. An ASME study indicates that every 1% reduction in friction can lead to a 0.5% increase in fuel efficiency. Yet, it’s vital to note that overloading these components can lead to rapid wear. Users often overlook the importance of load ratings. Many users may underestimate how load capacity affects their operational efficiency, causing premature failure.

Further, the application in robotics highlights both potential and pitfalls. Steel ball bearings provide smooth motion, but they can falter under extreme conditions. High-speed applications might lead to overheating. In contrast, while low-speed applications require a different set of tolerances. Understanding these nuances is key. Proper application not only improves performance but also prolongs lifespan, making it essential to match the right bearing with the right task.