In the world of manufacturing, choosing the right components is crucial. Experts emphasize the importance of quality in performance. James Carter, a leading engineer in the bearing industry, said, "The choice of bearings defines the efficiency of your machinery." This statement resonates deeply when we discuss the merits of the Bearing Roller Cylindrical.

Bearing Roller Cylindricals are designed to reduce friction while supporting heavy loads. They are vital in industries like automotive, aerospace, and heavy machinery. Their unique design allows them to withstand high pressure, making them an ideal choice. Yet, many industries overlook their significance. This oversight can lead to inefficiencies and increased maintenance costs.

In exploring the benefits of Bearing Roller Cylindricals, we must also reflect on our choices. Are we prioritizing quality over short-term gains? The right bearing can drastically influence operational success. Therefore, selecting Bearing Roller Cylindricals is not just a technical decision—it’s a strategic one. It invites us to examine our standards.

Understanding the functionality of bearing roller cylindrical components is essential for various industries. These rollers have a unique design that allows them to handle heavy loads with ease. This feature makes them ideal for applications where durability and reliability are critical. Their cylindrical shape provides a larger contact area, which reduces wear and tear, enhancing operational lifespan.

Tips: Regular maintenance is crucial. Inspecting the rollers frequently can help detect signs of damage early. Replace any worn components promptly to avoid larger issues down the line.

The effectiveness of bearing roller cylindrical units depends on their proper application. Using them in the right context is vital. Choose the correct size and load capacity based on specific requirements. Underestimating load capacity may lead to failure.

Tips: Keep records of performance. Tracking how these rollers perform can highlight potential problems. Also, consider environmental conditions. Extreme temperatures can affect their functionality. Always ensure they are suitable for the operational setting.

| Dimension | Material | Load Capacity (kg) | Speed Rating (RPM) | Operating Temperature (°C) | Applications |

|---|---|---|---|---|---|

| 10mm x 19mm x 5mm | Steel | 200 | 4000 | -20 to 100 | Automotive, Industrial Machinery |

| 15mm x 25mm x 7mm | Stainless Steel | 350 | 3500 | -30 to 120 | Food Processing, Pharmaceutical |

| 20mm x 30mm x 10mm | Bronze | 450 | 3000 | -20 to 100 | Marine Applications, Heavy Equipment |

| 25mm x 42mm x 15mm | Ceramic | 550 | 2500 | -40 to 150 | Aerospace, High-Temperature Applications |

| 30mm x 55mm x 20mm | Carbon Steel | 750 | 2000 | -20 to 100 | Construction Equipment, Manufacturing |

Bearing roller cylindrical designs provide key benefits in various industrial applications. These roller bearings are known for their high load capacity. According to a recent industry report, cylindrical roller bearings can handle radial loads better than standard ball bearings. They excel in demanding conditions where performance matters most.

A significant advantage is their ability to reduce friction. This leads to improved efficiency in mechanical systems. Industries, such as manufacturing and automotive, report up to 30% energy savings when using these bearings. The design allows for greater contact area, which increases durability. However, this durability can sometimes lead to overconfidence. Users may neglect regular maintenance, leading to potential failures.

Applications in heavy machinery also highlight the strengths of cylindrical roller bearings. They can withstand heavy vibrations and uneven loads. A study indicated that machines equipped with these bearings run 15% longer without failure compared to those with traditional bearings. Some industries still face challenges in selecting the right bearing size. A mismatch can result in premature wear or suboptimal performance. It's crucial to analyze specific needs before making decisions.

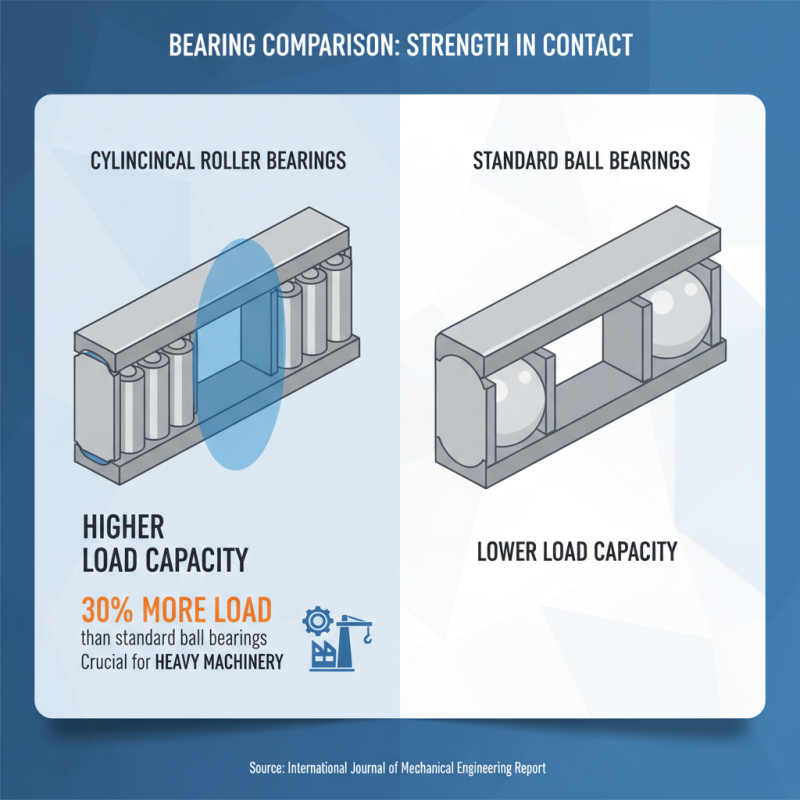

When comparing bearing roller cylindrical to other types, the advantages become clear. Bearing roller cylindrical offers a larger contact area. This leads to higher load capacity. According to a report by the International Journal of Mechanical Engineering, these bearings can handle 30% more load than standard ball bearings. This feature is crucial in heavy machinery where durability is essential.

However, there are trade-offs. Bearing roller cylindrical can be less adaptable in applications requiring high-speed performance. While they excel in load-bearing situations, their design may not perform well in fast-moving machines. Data suggests that their rotational speed is often 20% lower compared to other bearing types. This can be a significant concern for industries focused on efficiency.

It's also worth noting the maintenance aspect. Roller bearings typically require more frequent lubrication checks. This adds to the overall operational costs. In high-paced environments, this detail can be overlooked. Even with their robust advantages, businesses may need to weigh these factors carefully. The choice isn't always black and white; it reflects deeper industry needs and long-term strategies.

Bearing roller cylindrical structures are versatile and widely used in many industries. They excel in applications requiring high load capacity and durability. In construction machinery, these rollers support heavy loads and enhance operational efficiency. They endure harsh conditions, often exposed to dust, moisture, and extreme temperatures.

Another great example is in automotive applications. Bearings play a key role in reducing friction in engines and transmissions. This process improves fuel efficiency and extends the lifespan of components. However, improper maintenance can lead to failures, raising concerns about longevity and overall performance. It's crucial for engineers to regularly check and assess bearing conditions.

In the manufacturing sector, bearing roller cylindricals are essential in conveyor systems. They help facilitate smooth movement of goods, allowing for faster assembly lines. Problems arise, though, when these components wear out or misalign. This can lead to costly downtimes, highlighting the necessity of regular inspections. In summary, while these bearings offer numerous benefits, they require diligent monitoring to ensure optimal function.

Maintaining bearing roller cylindrical systems is critical for operational efficiency. Regular maintenance can extend lifespan and improve performance. Research indicates that properly maintained bearings can last up to five times longer than neglected ones, significantly reducing replacement costs.

It's essential to monitor lubricant quality. Contaminated grease can lead to premature wear. Using high-quality lubricants is a must. But, even the best lubricants fail without proper application. Following manufacturer guidelines decreases the risk of over-lubrication. This mistake can cause increased heat and eventually system failures.

Condition monitoring is another vital aspect. Sensors can track vibration levels and temperature. Anomalies in these readings often signal issues early, allowing for proactive maintenance. A study reveals that predictive maintenance reduces downtime by at least 25%. However, many industries still rely on reactive strategies, which can be more costly. Regular training sessions for technical staff can bridge this knowledge gap, enhancing maintenance strategies for improved reliability.