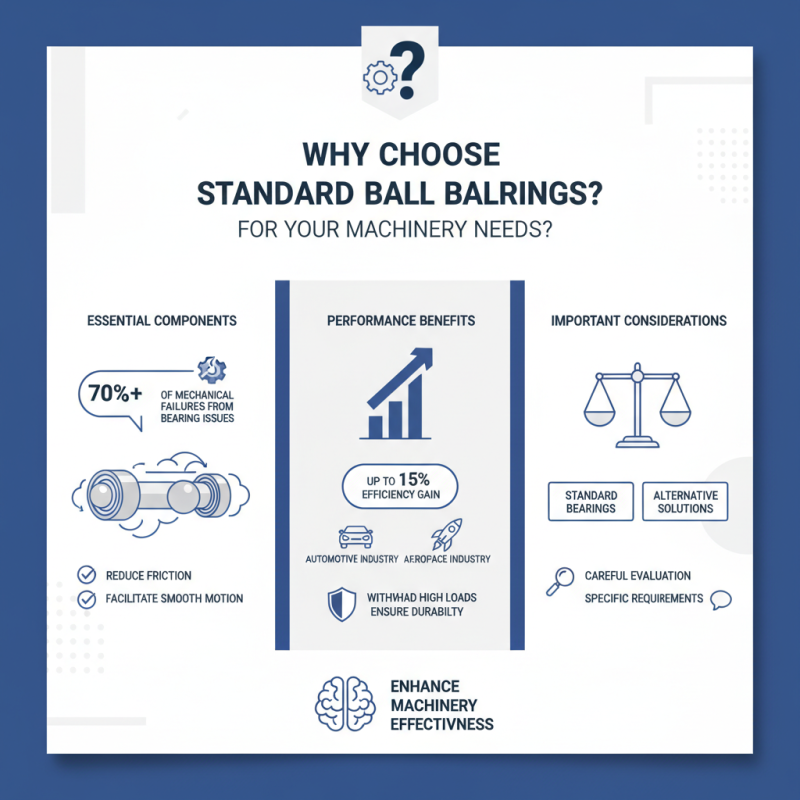

Standard Ball Bearings are essential components in machinery. They facilitate smooth motion and reduce friction. According to industry reports, over 70% of mechanical failures arise from bearing issues. This statistic highlights the importance of reliable bearings in various applications.

Choosing Standard Ball Bearings can significantly improve performance. These bearings are designed to withstand high loads and ensure durability. A study by the American Bearing Manufacturers Association shows that properly selected bearings can enhance operational efficiency by up to 15%. This efficiency is crucial in industries like automotive and aerospace, where precision matters.

However, it is important to acknowledge that not all machinery needs Standard Ball Bearings. In some cases, alternative solutions may perform better. This decision requires careful evaluation and reflection on specific requirements. Understanding the nuances of bearings enhances overall machinery effectiveness.

Standard ball bearings are crucial in many machinery applications. They help reduce friction and enhance performance. The design of these bearings allows for smooth operation, which is essential for machinery durability. Having the right bearings can improve efficiency and extend the life of equipment.

In addition to efficiency, standard ball bearings offer easy maintenance. They are widely available, making replacement straightforward. Many machines rely on these components for optimal performance. However, choosing the wrong type can lead to problems. It's important to evaluate load requirements and speed ratings carefully. Understanding these factors can prevent costly mistakes.

The versatility of standard ball bearings cannot be overstated. They fit various applications, from simple motors to complex industrial machines. However, they are not perfect. Sometimes, they may wear out quickly under heavy loads. Regular inspection is necessary to catch issues early. Skilled maintenance ensures longevity and reliability in operations.

| Feature | Description | Advantages |

|---|---|---|

| Durability | Built to withstand heavy loads and harsh conditions. | Longer service life, reducing maintenance costs. |

| Versatility | Compatible with various machinery types and configurations. | Eases integration into existing equipment. |

| Friction Reduction | Designed to minimize friction and wear during operation. | Improves efficiency, leading to energy savings. |

| Cost-effectiveness | Provides reliable performance at a lower price point. | Reduces overall machinery costs. |

| Ease of Maintenance | Simple to install and replace when necessary. | Lowers downtime for maintenance tasks. |

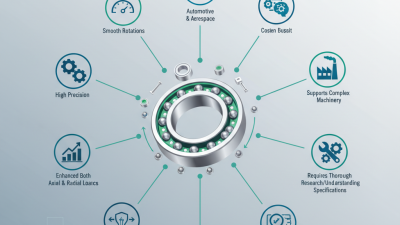

Standard ball bearings are essential in machinery. They have several key features that make them a preferred choice. These bearings are designed to support both radial and axial loads. This versatility allows them to perform well in various applications.

One notable feature is their low friction. Reduced friction leads to less heat generation. This can enhance equipment life. Additionally, their construction often includes durable steel or ceramic materials. These materials can withstand significant wear over time. However, they are not immune to damage. A sudden impact may cause a failure that is often overlooked.

The reliability of standard ball bearings also comes from their easy maintenance. Regular lubrication can prolong their life. However, users sometimes forget this crucial step. Neglecting maintenance could lead to decreased performance or premature failure. Ultimately, understanding these features can help users make informed choices for their machinery needs.

This chart illustrates the key features of standard ball bearings, highlighting their advantages in terms of load capacity, speed rating, durability, friction coefficient, and cost efficiency.

When it comes to machinery, choosing the right ball bearings is crucial. Standard ball bearings are versatile and widely used in various applications. They come in different types, each with unique characteristics. Understanding these types is essential for optimal performance.

There are deep groove ball bearings, which handle radial and axial loads well. They are common in electric motors and automotive applications. Then, we have angular contact bearings. These can manage both radial and axial loads at high speeds. They are ideal for high-precision machinery.

Keep in mind the importance of proper lubrication. Insufficient lubrication can lead to premature wear. Regular maintenance is key. Check for signs of damage regularly. Be attentive to unusual noises, as they may indicate underlying issues.

Tips: Always consult technical specifications before purchasing. Understand the load requirements of your machinery. Don’t overlook the importance of installation techniques. A wrong installation can affect bearing performance significantly.

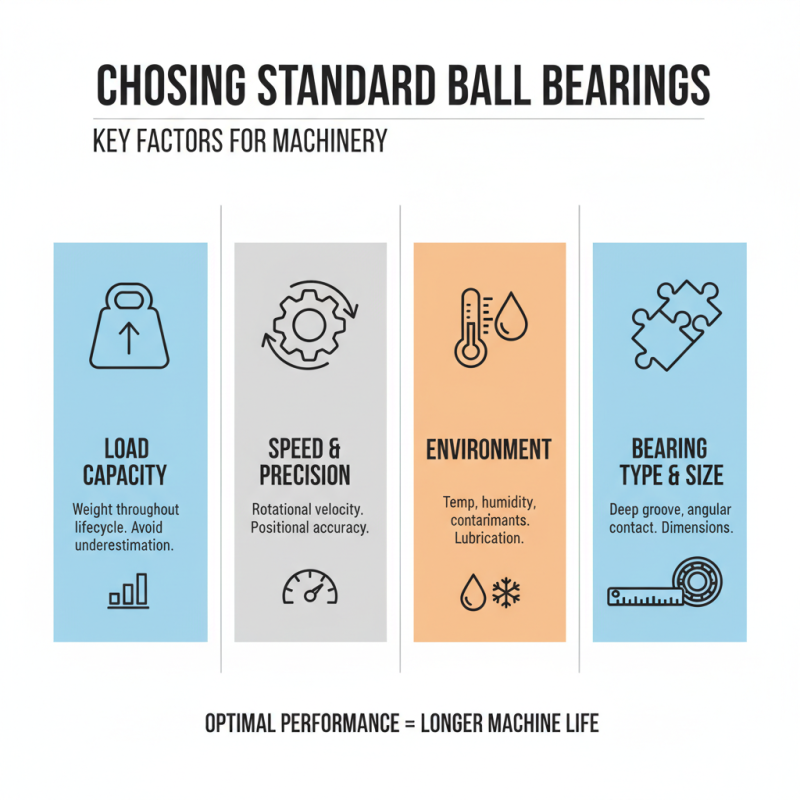

Choosing the right standard ball bearings for machinery is critical. There are several factors to weigh carefully. Load capacity is one of the most important. You should consider how much weight each bearing will bear throughout its lifecycle. Underestimating this can lead to failures.

Another vital factor is the environment where the bearings will operate. Dust, moisture, and extreme temperatures can dramatically affect performance. Bearings located in harsh environments may require additional sealing. This might increase cost but could lead to longer service life.

Finally, the size and fit of the bearings also matter. A bearing too loose will wobble. But one that is too tight might seize up. Achieving the right balance is essential, yet sometimes overlooked. Regular assessment and adaptation based on usage can help avoid potential issues. Consider all these elements carefully, and the machinery will run smoother for longer.

When it comes to machinery, the right components make all the difference. Standard ball bearings are popular for various applications due to their reliability. They reduce friction and allow for smooth movement. However, maintenance is often overlooked. Proper care ensures longevity.

Routine checks can catch issues early. Lubrication is vital for performance. Regularly inspect for wear and tear. Replacing parts at the right time prevents bigger problems down the line. Many operators wait too long to address minor issues, leading to failures. A small crack in a bearing can escalate into costly repairs.

Moreover, operating conditions significantly affect the lifespan of ball bearings. Dust and debris can cause wear. Keeping the environment clean is essential. Machines may run fine for a while, but neglecting maintenance can lead to unexpected shutdowns. Understanding how to care for your equipment is key to its success.