Choosing the right bearings ball is crucial for any engineering project. The ball bearing industry has seen significant growth, with market reports suggesting a rise to $20 billion by 2025. Quality bearings can enhance performance and durability, making the selection process vital. However, with so many options available, it can be overwhelming for project managers and engineers.

Expert John Smith, a leading figure in the bearings ball industry, once stated, "Selecting the right bearings is the foundation of a successful project." This indicates how important it is to understand the specifications required for specific applications. Factors such as material, load capacity, and size are essential in making an informed selection.

Mistakes in choosing bearings can lead to project delays and increased costs. Yet, many overlook these details. Reflecting on your choices can sharpen your understanding. Aim for a balance between cost and quality. Choosing wisely will pave the way for project success.

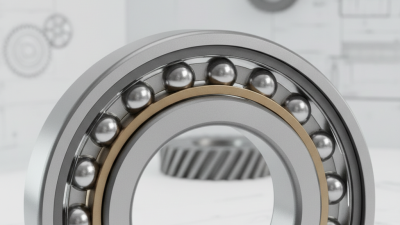

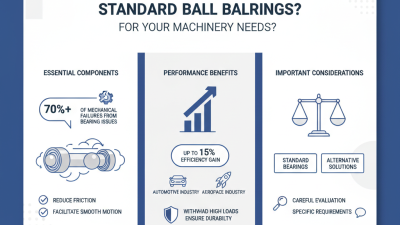

Ball bearings are crucial in engineering projects. They reduce friction and increase efficiency. This small component can greatly enhance the performance of machines. When designing a project, think about how ball bearings will fit into the system. Size matters; the wrong size can lead to issues. It can change how well a mechanism operates.

Consider the materials used in ball bearings. Steel is common, but there are other options. Ceramic bearings offer different advantages. They can be lighter and more durable. However, they may not be suitable for all applications. This decision requires careful thought.

The operating environment also affects the choice. For dusty or wet conditions, special coatings may be necessary. If neglected, this can lead to failures. Engineers must often assess potential pitfalls. Choosing the right ball bearings may seem straightforward, but the details matter greatly. Ensuring the right fit can mean the difference between success and failure in a project. It's essential to reflect on these aspects during the planning phase.

This chart illustrates the importance of various selection criteria when choosing ball bearings for engineering projects. Material and load capacity are the most critical factors, followed by speed rating, temperature range, and price.

When selecting ball bearings for specific applications, understanding their types is crucial. There are several common types, including deep groove, angular contact, and thrust bearings. Deep groove ball bearings are the most versatile. They perform well in various settings. According to industry data, approximately 40% of all bearing sales are deep groove types. They handle both radial and axial loads efficiently.

Angular contact bearings excel in applications requiring high-speed operations. They can manage both axial and radial loads but in a specific direction. This is significant for gearboxes and electric motors. Thrust bearings are essential when axial loads predominate. They are often used in applications like automotive transmissions. The proper selection can enhance performance and longevity.

Tips: Always evaluate the load conditions. Consider both speed and temperature factors. A mismatch can lead to premature failure. Examine your project’s requirements closely. Small oversight can lead to considerable issues later. Each bearing type serves a unique purpose. Understanding this can save time and costs.

| Type of Ball Bearing | Description | Specific Applications |

|---|---|---|

| Deep Groove Ball Bearings | The most common type of ball bearing, suitable for high speeds and radial loads. | Electric motors, automotive applications, and household appliances. |

| Angular Contact Ball Bearings | Designed to support both radial and axial loads, allowing for higher speed applications. | Machine tool spindles and automotive wheel hubs. |

| Self-Aligning Ball Bearings | Features two rows of balls and a common sphered raceway in the outer ring, allowing for misalignment tolerance. | Agricultural machinery, conveyors, and housing applications. |

| Thrust Ball Bearings | Designed to handle axial loads in one direction, consisting of two washers and balls. | Automotive transmissions and rotating shafts. |

| Miniature Ball Bearings | Compact and lightweight, perfect for small applications with limited space. | Watch mechanisms, robotics, and miniature devices. |

When selecting ball bearings for your project, several factors come into play. The type of application is crucial. For high-speed operations, look for materials that can withstand friction. Applications involving heavier loads require bearings with higher load ratings. The environment matters too. If bearings will face moisture or dust, consider sealed or shielded options.

Choosing the right size is often overlooked. Measure the shaft and housing carefully. An incorrect fit can lead to premature failure. There are different types of ball bearings, such as deep groove or angular contact. It’s important to understand how each type works in your specific use case.

Don’t forget about lubrication. Proper lubrication can extend bearing life, but over-lubrication can also be an issue. Experimenting with different lubricants may yield better results. Lastly, be aware of your budget. Sometimes, a more expensive option will save costs in the long run. However, going too cheap can lead to trouble. Select wisely and reflect on what works best for your needs.

When selecting ball bearings, material choice is crucial. Common materials include steel, ceramic, and composite options. Each has its pros and cons.

Steel ball bearings are prevalent due to their strength and durability. They can handle heavy loads and high speeds. However, they are susceptible to rust and corrosion, making them less ideal for wet environments. A report by the American Bearing Manufacturers Association notes that over 55% of bearings in industrial applications are made from steel. This reflects their popularity but also highlights the need for protective coatings or lubrication to extend their lifespan.

Ceramic ball bearings offer a lightweight alternative. They resist wear and are corrosion-resistant. They can significantly reduce friction, improving efficiency. However, they are often more expensive and brittle. According to a study by Research and Markets, ceramic materials are expected to account for 25% of the bearing market by 2025. This shift suggests an increasing interest in their advantages, despite their brittle nature, which demands careful handling.

Composite bearings combine materials, offering a middle ground but can be challenging to optimize in specific applications.

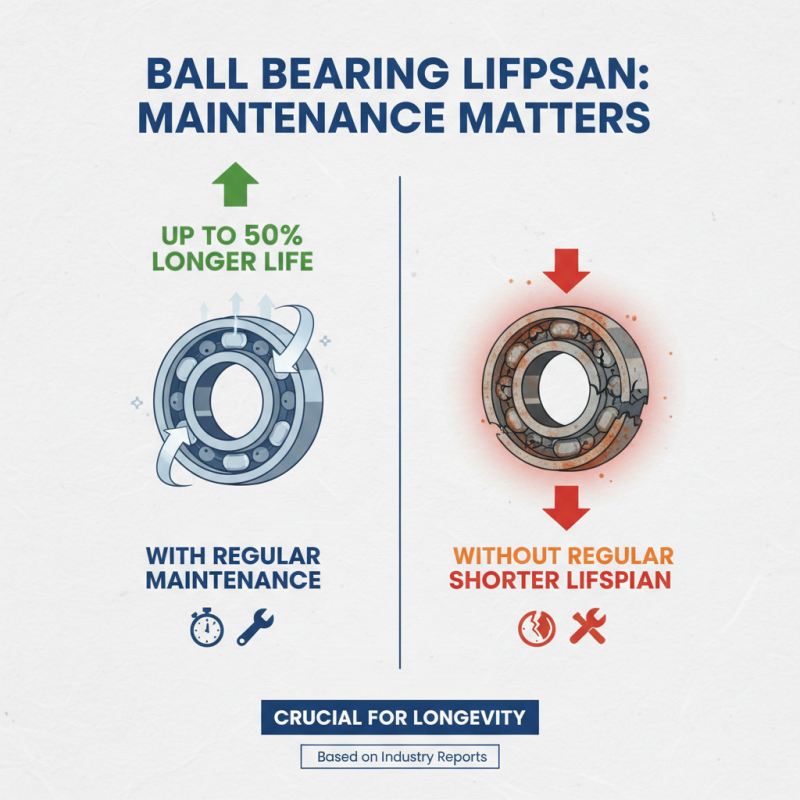

When it comes to ball bearings, regular maintenance is crucial. Proper care can significantly extend their lifespan. According to industry reports, bearings that receive routine attention can last up to 50% longer than those that don't.

One key tip is to keep bearings clean. Dirt and debris can cause wear. Use a soft cloth to wipe exterior surfaces. Lubrication is equally important. Regularly apply the right lubricant to reduce friction. Over time, oil breaks down. Monitor lubricant levels and replace it as needed.

Another consideration is temperature control. Heat can jeopardize bearing integrity. Ensure that bearings operate within the recommended temperature range. Install heat shields if necessary. Finally, be mindful of any unusual noises during operation. These could signal problems that need immediate attention. Addressing potential issues early can save time and money in the long run.