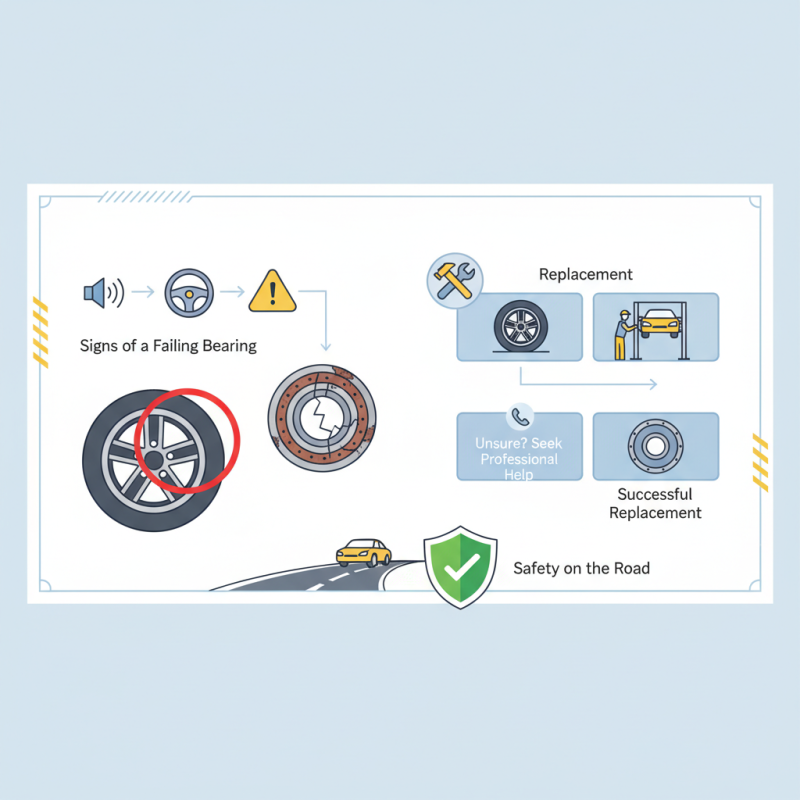

Auto wheel bearings are essential for the smooth operation of your vehicle. These small parts enable the wheels to rotate seamlessly. Over time, they can wear out or become damaged. Recognizing the signs of a failing auto wheel bearing is crucial for safe driving.

Unusual noises, such as grinding or humming, often indicate a problem. Vibration in the steering wheel can also signal wear. These issues may seem minor initially, but ignoring them can lead to serious risks. It’s important to pay attention to your vehicle’s performance.

Replacing auto wheel bearings requires specific tools and knowledge. Many may underestimate the complexity of the task. Taking the right steps can simplify the process. However, if unsure, seeking professional help is wise. A well-maintained wheel bearing is vital for safety on the road.

Wheel bearings play a crucial role in vehicle safety and performance. They support the weight of the vehicle, allow wheels to rotate smoothly, and help with steering. According to industry reports, a significant percentage of vehicle issues stem from faulty wheel bearings. In fact, improper maintenance can lead to decreased fuel efficiency and costly repairs.

Recognizing the signs of worn or damaged wheel bearings is essential. Common indicators include odd noises while driving and uneven tire wear. Many drivers overlook these signs, leading to further complications. Regular checks can save time and money in the long run.

Tip: Inspect your wheel bearings every 30,000 miles to ensure optimal performance. Keep an eye on any vibrations or noise changes. Addressing issues early can prevent dangerous situations on the road. Don't ignore these warning signs. Awareness is key to safe driving.

Worn wheel bearings can significantly affect your driving experience. One of the most common signs is noise. You might hear a grinding or humming sound, especially when turning. This noise often increases with speed. It can become quite annoying and indicates that something is wrong. Pay attention to how these sounds change as you drive.

Vibration is another telltale sign. If your steering wheel shakes or vibrates when driving, it could be due to bad wheel bearings. This feeling can be unsettling and may indicate uneven wear. Sometimes, you might also notice handling issues. Your vehicle may pull to one side or feel loose while driving.

These symptoms can stem from multiple causes, but worn bearings are a likely suspect. Regular inspections can help catch these issues early. Driving with damaged wheel bearings is risky and can lead to more extensive repairs.

When inspecting or replacing auto wheel bearings, having the right tools is essential. You'll need a jack to lift the vehicle safely. A lug wrench helps to remove the wheel. Pliers can assist with clips and small parts. A bearing puller makes the removal easier. Don't forget a torque wrench for proper reattachment.

Tips: Always ensure your workspace is clean and well-lit. Gather all tools before you start. It saves time and minimizes frustration. Double-check that you are using the correct tools for your specific vehicle model.

Safety gear is also crucial. Wear safety glasses to protect your eyes. Gloves can prevent injuries while handling sharp edges. Be cautious of the weight of the vehicle. A misplaced jack can lead to accidents. Take breaks if needed. Mechanical tasks can be tiring and errors may occur when fatigue sets in.

Tips: Document your steps during the process. Write down which parts were removed. It helps during reassembly. If something doesn’t fit, step back and reassess. It’s better to take your time than to rush. Mistakes in reassembly can lead to more significant issues.

Identifying faulty wheel bearings is crucial for vehicle safety. A noticeable sound often indicates issues. A grinding or humming noise can signal that bearings are worn out. The National Institute for Automotive Service Excellence reports that about 30% of wheel bearing failures are due to improper installation. This highlights the importance of accurate assessment.

During inspection, pay attention to any play in the wheel. A slight wiggle can mean trouble. Check for rust or damage on the bearing surface. The Automotive Service Association notes that proper lubrication is critical. Poor lubrication contributes to 25% of bearing failures. Inspect your vehicle regularly to catch problems early.

Driving habits also play a role. Frequent sharp turns or heavy loads can accelerate wear. The average lifespan of wheel bearings varies, but they typically last about 85,000 miles. However, some may need replacement sooner. Always consider unique driving conditions and your specific vehicle's needs. Regular check-ups are essential to ensure safety and performance.

This chart illustrates the severity of various indicators for faulty auto wheel bearings. Each value represents a scale from 1 to 10, where higher values indicate more significant concerns that may require attention or replacement of wheel bearings.

Replacing wheel bearings is a critical task for vehicle maintenance. Safety should be your top priority. Always wear protective gear, including gloves and safety glasses. Use a jack that can support your vehicle’s weight. Make sure the vehicle is on a level surface. Inspect the brakes thoroughly; dirty or worn brakes can lead to accidents. A small oversight could be catastrophic.

When you actually start the replacement, be cautious with tools. They can slip and cause injuries. Keep your workspace clean and organized. Distractions can lead to mistakes. Check for any signs of damage on other components while you work. If a part looks worn, consider replacing it. It's better to do things right the first time.

Finally, don’t rush through the process. Proper installation is key to safety. Take breaks if you feel fatigued. It’s okay to ask for help. A second pair of eyes can catch errors you might miss. Remember, your safety and that of others depend on your attention to detail.