Standard Ball Bearings are crucial components in many machines. These bearings reduce friction and enhance performance, making them essential for efficiency. According to a report by MarketsandMarkets, the market for ball bearings is projected to reach $99.2 billion by 2025. Experts emphasize the importance of understanding their function and applications.

Dr. Emily Carter, a leading expert in mechanical engineering, states, "To innovate in machinery, we must master the basics like the Standard Ball Bearing." This highlights the significant role these bearings play in modern technology.

Despite their simple design, Standard Ball Bearings can be overlooked. Some engineers may underestimate their importance. Recognizing the value they add is critical to improving machine performance and lifespan. Proper use of these bearings can lead to major efficiency gains in various industries.

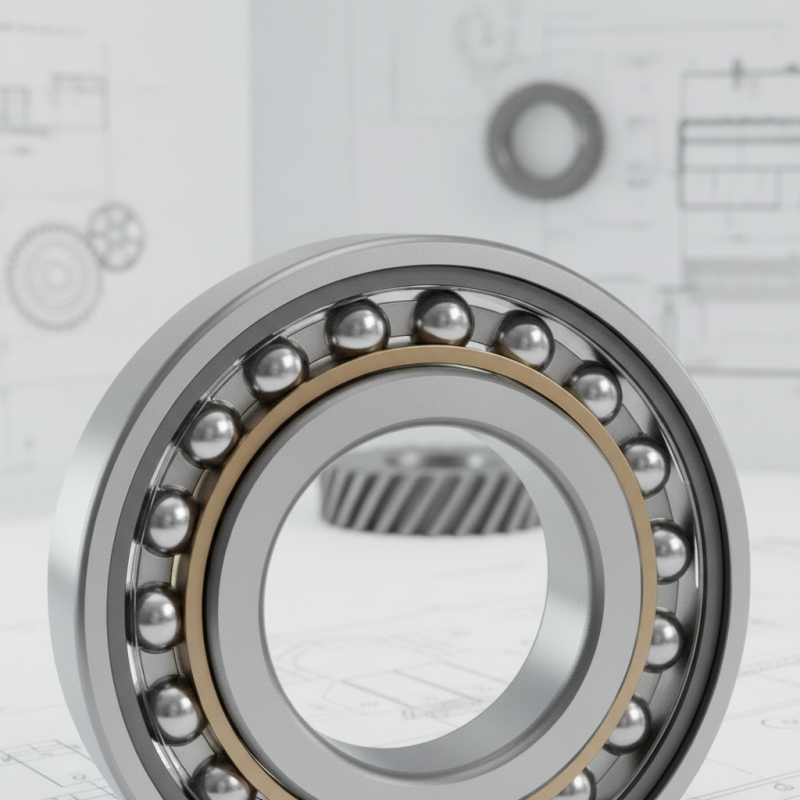

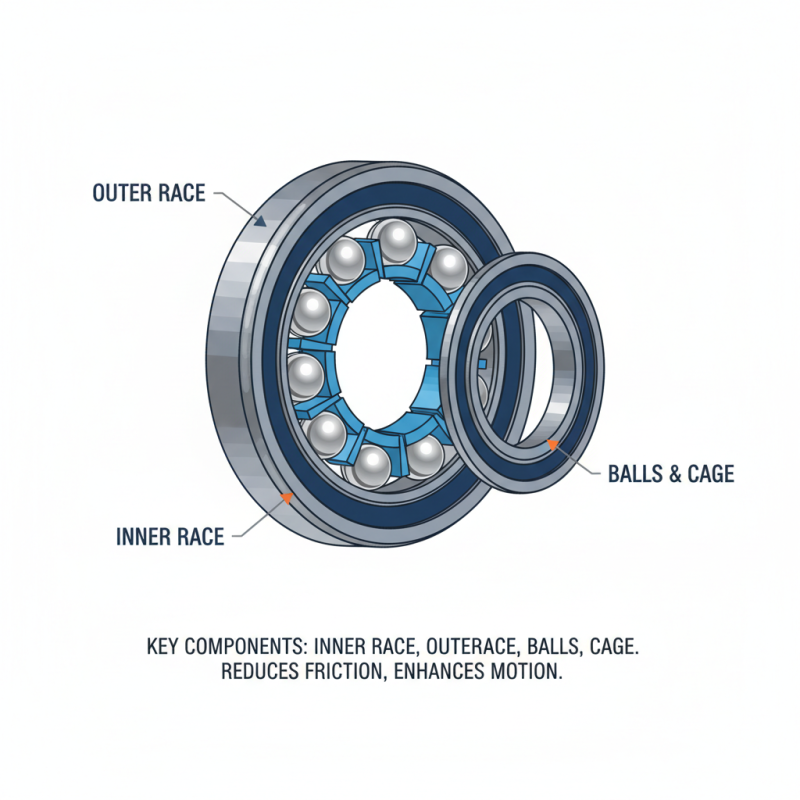

A standard ball bearing is a crucial component in many machines. It consists of an outer race, an inner race, and several small balls in between. These balls allow for smooth rotation and reduce friction. The design is quite simple, yet remarkably effective.

Ball bearings come in different sizes. They vary in applications, from tiny ones in watches to large ones in industrial machines. When installed properly, they enable parts to spin freely, enhancing efficiency. But installation is key. A poor fit can lead to premature wear or failure.

Over time, ball bearings can develop issues. Dust and debris may accumulate inside, which can hinder performance. Regular maintenance can mitigate these problems. However, many overlook this step until it's too late. Noticing unusual sounds or vibrations can indicate trouble. Staying vigilant is essential for longevity.

A standard ball bearing consists of several key components that work together to reduce friction and enhance motion. The primary parts include the inner race, outer race, balls, and cage. The inner and outer races provide the surfaces upon which the balls roll. These races are typically made from steel or ceramic materials, chosen for their durability and resistance to wear.

The balls in the assembly act as the primary point of contact. Their spherical shape allows them to rotate smoothly within the races. This design minimizes surface contact, which reduces friction and heat generation. Many standard ball bearings are designed to withstand loads of up to 1,000 pounds, depending on their size and configuration. A study by the American Bearing Manufacturers Association found that the proper selection of bearing components can lead to a 50% longer service life.

The cage, or retainer, is an often-overlooked element. It keeps the balls evenly spaced and prevents them from colliding. However, not all cages are created equal. Some are made from plastic, which can be less effective under high loads or temperatures. Engineers sometimes face challenges when selecting materials for each component. Ignoring these subtle details can lead to suboptimal performance and premature failure in applications. Maintaining optimal combinations of these components is crucial for achieving high efficiency.

Ball bearings are crucial components in many machines. Their primary function is to reduce friction between moving parts, resulting in smoother operation and less wear on components. The design usually includes small balls housed within two rings. These rings, known as raceways, guide the balls as they revolve.

The working principle of ball bearings relies on the distribution of load. When a load is applied, the balls bear the weight and allow rotational movement. This setup minimizes direct contact between surfaces, significantly decreasing friction. However, alignment issues can arise. If the balls are misaligned, wear increases rapidly.

It's important to regularly check the condition of bearings. An unnoticed flaw can lead to equipment failure.

Temperature can also affect performance. High temperatures might cause lubricant breakdown, leading to increased friction. Hence, lubrication is crucial for efficient operation. Regular maintenance can ensure longevity and efficient function. Observing these details helps in understanding how ball bearings operate and why they are vital in daily machinery.

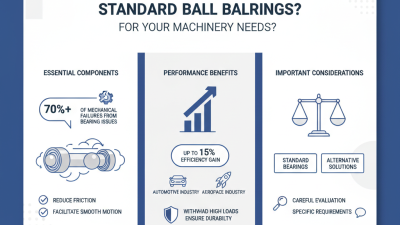

Ball bearings play a crucial role in various industries. They reduce friction between moving parts. This improves the efficiency of machines. In manufacturing, ball bearings support conveyor systems. They enhance load-carrying capacity and increase speed. Without them, systems would wear out quickly.

In automotive applications, ball bearings ensure smooth wheel rotations. They minimize energy loss in drive shafts. This leads to better fuel efficiency. In the aerospace sector, bearings withstand extreme conditions. They are vital in engines and landing gear. These parts require precise engineering to ensure reliability.

Yet, not all applications see optimal performance. Sometimes, installation errors occur. Misalignment can lead to premature failure. Regular maintenance is essential. Neglected bearings may fail, leading to costly downtime. Understanding these factors can improve overall functionality and safety in every industry.

Ball bearings are critical in various machinery operations. Their efficiency relies heavily on routine maintenance. Neglecting this aspect can lead to premature failure. According to a report by the International Journal of Engine Research, nearly 30% of equipment failures are due to poor bearing maintenance. Regular inspections can help identify issues before they escalate.

Lubrication is vital for ball bearing longevity. Proper lubrication reduces friction and wear. Studies show that bearings can last up to 50% longer when adequately maintained. However, over-lubrication can be just as harmful. It can lead to overheating and excess pressure within the bearing. Identifying the right amount of lubricant is a challenge for many operators.

Even with meticulous maintenance, issues can still arise. Variations in load, speed, and environment can affect bearing life. Monitoring these factors is crucial. A comprehensive analysis may reveal that some bearings require more attention than others. The key is not just routine checks but understanding the specific needs of each application.