Choosing the right Bearing Roller Cylindrical can significantly impact your project’s success. These components are vital for efficient machine operation and durability. When selecting, consider the load capacity, speed, and environmental conditions. Each bearing is designed for specific applications, so understanding these factors is essential.

Bearings come in various sizes and specifications. It may feel overwhelming because of the options available. A wrong choice can lead to premature wear or failure. Therefore, research is crucial. Pay attention to manufacturer guidelines and technical data sheets. Every detail matters when optimizing performance.

Lastly, remember that installation plays a role in functionality. Proper fitting can prevent damage and enhance longevity. Reflect on previous experiences where choices led to issues. Learning from past mistakes can guide better decisions now. With careful consideration, the perfect Bearing Roller Cylindrical is within reach.

Roller cylindrical bearings are crucial components in many machines. They are designed to handle heavy loads and operate efficiently in various conditions. Understanding how they work can help you make better choices for your applications.

These bearings have cylindrical rolling elements. This design allows them to support larger radial loads compared to other types. However, it’s important to note that they can also be sensitive to misalignment. Such issues often lead to premature wear or failure. Choosing the right size is vital. An oversized bearing can lead to unnecessary costs, while an undersized one might not bear the load properly.

Consider the operating environment too. Temperature fluctuations and exposure to moisture can affect performance. It’s wise to think about lubrication methods. Many users overlook this aspect, leading to increased friction. Regular maintenance checks can help identify issues early. Sometimes, these small details can significantly impact the longevity of the bearings.

| Dimension (mm) | Load Rating (kN) | Speed Rating (RPM) | Material | Application |

|---|---|---|---|---|

| 20 x 40 | 6.5 | 6000 | Steel | Electric Motors |

| 30 x 55 | 15.0 | 4500 | Stainless Steel | Hydraulics |

| 40 x 70 | 25.0 | 3000 | Chrome Steel | Heavy Machinery |

| 50 x 90 | 35.0 | 2500 | Carbon Steel | Automotive |

| 60 x 100 | 50.0 | 2000 | Bronze | Marine Applications |

When selecting a cylindrical roller bearing, it’s crucial to identify your specific application needs. Start by considering the load capacity requirements. Different applications may impose varying loads. Understand whether your machinery requires a high load-carrying capacity or only light support. A mismatch can lead to premature failure.

Next, assess the operating environment. Factors such as temperature, humidity, and exposure to contaminants can impact performance. For example, certain lubricants may not withstand high temps. This could be a significant oversight. Equally important is the speed at which the bearing will operate. High speeds may require special designs. You might also think about noise levels. Sometimes, the quiet operation is as vital as the load capacity itself.

Don’t forget to evaluate installation processes. Some bearings may require special tools or techniques. This may complicate efforts, leading to potential delays. Reflecting on past experiences can help you avoid pitfalls. Common issues arise when there is insufficient clearance or misalignment. Taking the time to define these specifics is essential for preventing costly mistakes.

When selecting a cylindrical roller bearing, material considerations are critical for both durability and performance. Steel is the most common choice, renowned for its strength. However, it can be prone to corrosion in damp environments. In such cases, stainless steel might be a better option. It's resistant to rust but can be more expensive. Considering your specific needs will guide your choice.

Alternative materials, like plastic or ceramic, offer unique benefits. Plastic bearings can reduce weight and friction, ideal for lightweight applications. Yet, they may not handle heavy loads well. Ceramic options provide excellent wear resistance, suitable for high-speed applications. However, they're brittle and can crack under impact. Evaluating the application context is essential for making the right decision.

Sometimes, balancing cost with performance can lead to compromises. Cheaper materials may save money now but could lead to failures later. Investing in the right materials initially often pays off, enhancing operational efficiency. Regularly assessing whether your choices meet operational needs is crucial for maintaining performance.

When selecting cylindrical roller bearings, sizing and load capacity play vital roles. The outer diameter, inner diameter, and width must be compatible with your machinery. Too tight of a fit can cause friction. This can lead to overheating and premature failure. Conversely, an overly loose fit can lead to misalignment. Misalignment can wear down components faster than expected.

Load capacity is another crucial factor. Consider static and dynamic loads your bearing will endure. Static loads are those that remain constant, while dynamic loads change over time. A bearing needs to withstand the maximum load during operation. Underestimating these loads can result in bearing collapse.

It’s important to reflect on your choices. Many forget to calculate factors like temperature. Higher temperatures can affect materials’ properties. You want to ensure longevity in your bearings. Adequate lubrication is also essential. Neglecting this can lead to early wear and failure. Keep these elements in mind to achieve the best performance from your cylindrical roller bearings.

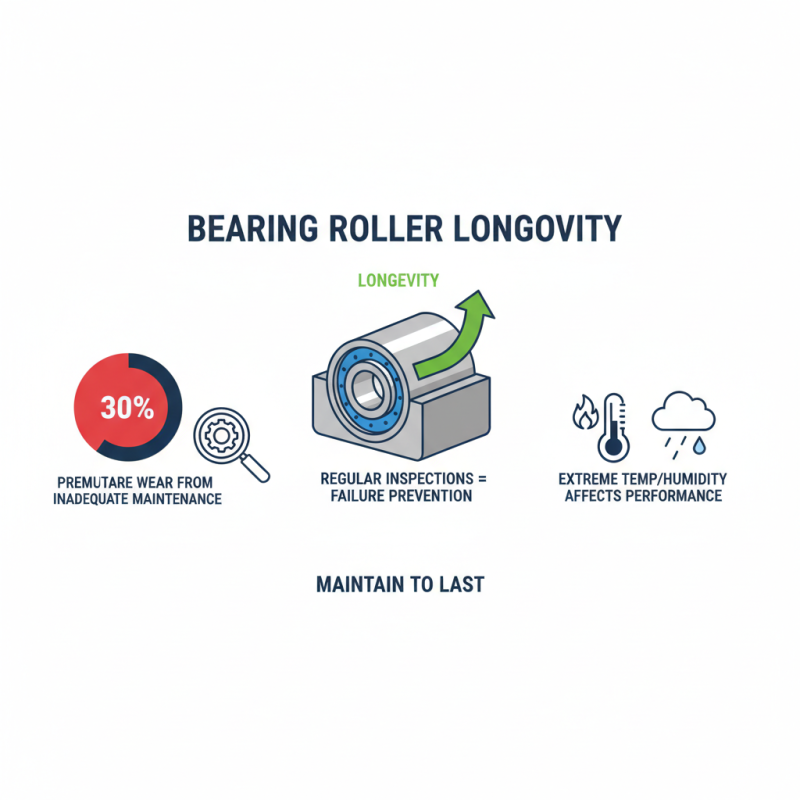

Maintaining bearing roller cylindrical components is crucial for their longevity. Regular inspections can prevent potential failures. Research shows that nearly 30% of premature wear is due to inadequate maintenance. Understanding the unique operating conditions is essential. For example, extreme temperatures or humidity can drastically affect performance.

Lubrication plays a critical role in extending the life of these bearings. Using the right lubricant reduces friction significantly. It's surprising that about 70% of bearing failures stem from improper lubrication techniques. While it may seem straightforward, many overlook specific requirements. For instance, too much or too little grease can lead to issues over time.

Another aspect to consider is contamination. Small particles can cause significant damage. Studies indicate that just 10 microns of debris can result in rapid deterioration. Regular cleaning and proper sealing mechanisms are ways to mitigate this risk. Many users have reported success after adopting these proactive measures. Reflecting on past experiences helps in making better choices moving forward.