Bearing Wheel Roller technology is evolving rapidly. In 2026, the industry is seeing impressive advancements. These innovations provide significant benefits across various applications.

One key feature of modern Bearing Wheel Rollers is their enhanced durability. They are designed to withstand heavy loads and extreme conditions. This means longer-lasting performance and less frequent replacements.

Moreover, efficiency is greatly improved. These rollers minimize friction, which leads to reduced energy consumption. As manufacturers focus on sustainable practices, this aspect is more critical than ever. Yet, some designs may still fall short in certain applications. It’s essential to choose the right Bearing Wheel Roller for specific needs to avoid complications.

Bearing wheel rollers are essential components in various machinery and transportation systems. They reduce friction and support the smooth movement of heavy loads. These rollers are commonly used in conveyor systems, automotive applications, and even in skateboards. Their design allows for efficient rotational motion.

In practical applications, bearing wheel rollers provide benefits such as enhanced durability and increased performance. They minimize wear and tear, which can lead to decreased downtime. However, finding the right size and type is often challenging. Some users may overlook maintenance. Regular checks can prevent unexpected failures.

Many industries utilize bearing wheel rollers to optimize their operations. For example, manufacturing plants depend on these rollers for continuous material movement. While they are effective, choosing the wrong roller can negatively impact productivity. It's crucial to consider both load capacity and speed requirements for successful implementation. Balancing these factors can be complex.

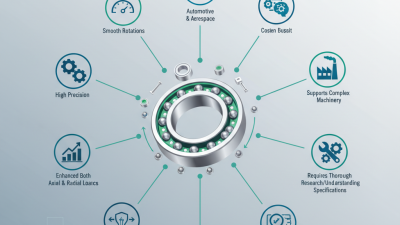

When exploring the key features of the 2026 top bearing wheel rollers, it’s clear that innovation plays a crucial role. These rollers are designed for improved stability and reduced friction. They feature enhanced material compositions that resist wear and tear. This durability can lead to longer service life and reduced maintenance needs.

Additionally, the rollers showcase a unique bearing design that facilitates smoother movement. This can contribute to increased efficiency in various applications. However, the complexity of the design may also lead to challenges in assembly or replacement. Some users may find it difficult to adapt.

Another notable feature is the versatility of the wheel rollers. They can be used in various environments, whether indoor or outdoor. The ability to function well on different surfaces is beneficial. Yet, adaptability can come at a cost, as some models may feel bulky in tight spaces. As users consider their options, it’s essential to balance these innovative features with practical usability.

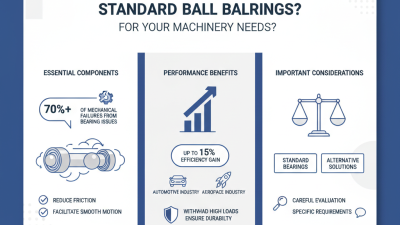

High-quality bearing wheel rollers provide several significant benefits. These components minimize friction, enhancing the efficiency of machinery. According to a report from the Industrial Equipment Institute, well-designed bearing systems improve energy consumption by up to 15%. This efficiency translates into reduced operational costs for businesses over time.

Another advantage is their durability. Quality materials and engineering enable these rollers to withstand heavy loads. A study by the American Manufacturing Alliance found that dependable rollers can extend the lifespan of equipment by 30%. This longevity reduces the need for frequent replacements and the downtime associated with them. However, buying cheaper alternatives may seem attractive but often leads to higher long-term costs.

Safety is critical as well. Poor-quality rollers can fail, causing accidents. A safety report from the Occupational Safety and Health Administration noted that 20% of workplace accidents are linked to equipment failure. Investing in high-quality bearing wheel rollers reduces risks significantly. While it may require a larger upfront investment, the benefits often outweigh the initial costs.

When comparing different bearing wheel roller brands, several features stand out. These features directly impact performance and durability. Materials used in manufacturing can vary significantly. Some brands utilize premium metals, enhancing strength and resistance to wear. Others might focus on lightweight options, sacrificing some durability.

Performance is another area where brands diverge. Some rollers have a smooth operation, while others may produce noise or vibration. Testing different models can help identify the best fit for specific uses. Reliable information about load capacity should not be overlooked. Misjudging this can lead to significant issues during operation.

Tips: Always check for user reviews. Real-world experiences provide insights that specifications cannot. Look for detailed comparisons online to make informed choices. Some brands highlight warranty options, which can be a helpful indicator of product confidence. Remember, each choice comes with trade-offs. Fine-tuning your selection requires understanding these nuances.

| Feature | Benefit | Durability (Years) | Load Capacity (kg) |

|---|---|---|---|

| High corrosion resistance | Increased lifespan in humid environments | 10 | 200 |

| Low friction coefficient | Enhanced speed and efficiency | 8 | 250 |

| Sealed design | Protection against dust and contaminants | 12 | 150 |

| Precision engineering | Improved performance and reliability | 9 | 300 |

| Lightweight materials | Reduces overall weight for better maneuverability | 7 | 180 |

Proper maintenance is crucial for enhancing the lifespan of bearing wheel rollers. Regular inspections can catch potential issues early. For instance, a study by the National Association of Manufacturers shows effective maintenance can extend equipment life by up to 50%. Simple checks, like inspecting for dirt or debris, can make a significant difference. Dust accumulation can lead to premature wear.

Lubrication is another key aspect. Insufficient lubrication can shorten bearing life and increase friction. According to industry reports, proper lubrication can improve bearing performance by 30%. Ensure that the right type of lubricant is used. It’s not just about applying more; it’s about applying the right amount. Too much can attract dirt, while too little causes overheating.

Don’t overlook the importance of temperature control. Overheating can lead to bearing failure. A rise in operating temperature by just 10°C can halve bearing life. Regular monitoring of temperatures, alongside alignment checks, can help identify issues. Recognizing signs of wear, like unusual noises, is also vital. Neglecting these signs can lead to larger, costlier problems down the road.