The demand for Standard Ball Bearings in industrial applications continues to rise. According to a recent report by Allied Market Research, the global ball bearing market is projected to reach $15 billion by 2026. This growth highlights the importance of choosing the right bearing type for efficiency and longevity in mechanical systems.

Industry expert Dr. John Smith, a leading figure in bearing technology, states, "Selecting the appropriate Standard Ball Bearing is crucial to enhance performance and reduce maintenance costs." This insight reflects the complexity of bearing applications across various sectors. Many companies overlook the significance of material, design, and load capacity, which can lead to unexpected failures.

In specific industries, like automotive and aerospace, understanding Standard Ball Bearing variations is essential. The challenges in maintaining optimal performance often stem from inadequate knowledge. Some manufacturers may underestimate the critical role these components play, leading to inefficiencies. Awareness and education in this field must improve to align with technological advancements.

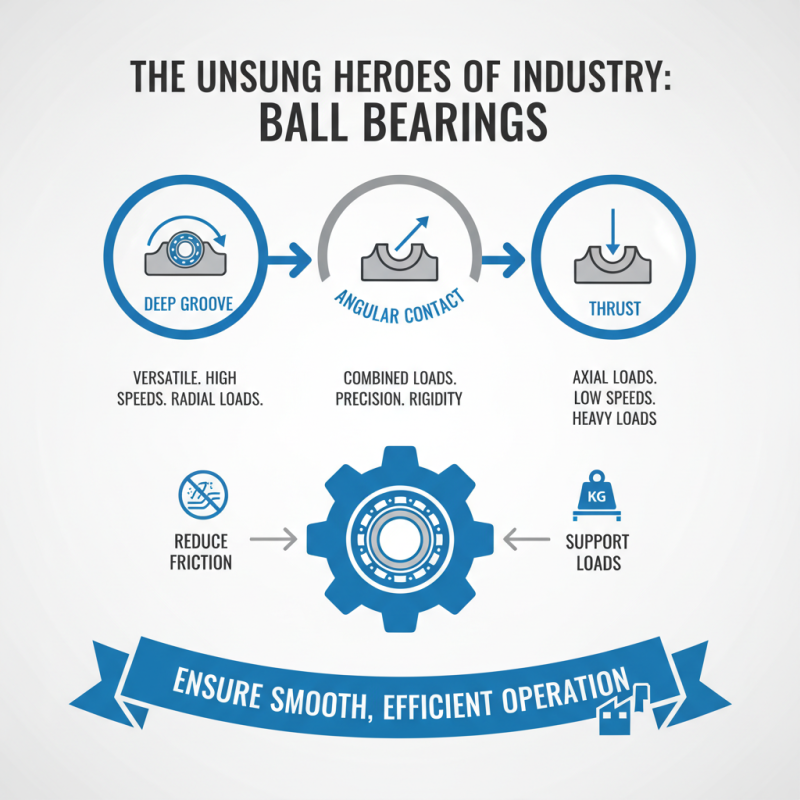

Ball bearings play a crucial role in industrial machinery. They reduce friction and support loads, ensuring smooth operation. Various types of ball bearings are suitable for specific applications. The most common types include deep groove, angular contact, and thrust ball bearings.

Deep groove ball bearings are versatile. They handle radial and axial loads effectively. These are often found in electric motors and pumps. Their design allows for high speeds and durability. Angular contact ball bearings are designed for simultaneous loads. They excel in applications where axial precision is vital. This makes them ideal for gearboxes and spindles. Thrust ball bearings, on the other hand, are used in low-speed applications. They support axial loads well, which makes them common in automotive applications.

Tip: Always match the bearing type to the application requirements. Using the wrong type can lead to premature failure. Regular maintenance is also essential. Inspect and lubricate bearings to extend their lifespan. Remember, each machinery setup is unique. Consider consulting with a specialist if unsure about your choice. This ensures optimal performance and reliability in operations.

Choosing the right ball bearings for industrial applications can be challenging. Key factors like load capacity, speed, and environment must be considered. Load capacity relates to how much weight the bearing can handle. If the load exceeds the capacity, it results in failures. Speed affects how efficiently the bearing operates under different conditions. Therefore, it is crucial to assess both factors together.

Environment plays a vital role in selection. Bearings used in corrosive environments need special materials. For example, stainless steel can offer better resistance. Temperature variations also matter. High temperatures can weaken the bearing’s integrity. Choose materials that withstand these conditions for better longevity.

Tips: Evaluate your application carefully. Look at the operating environment closely. Try testing with various types before making a final decision. Don't overlook the importance of maintenance. Regular checks can reveal wear and prevent unexpected downtime.

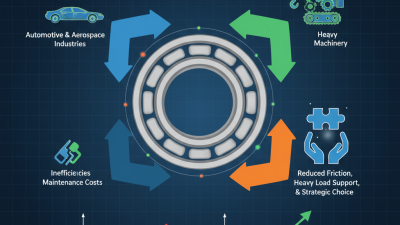

The use of top standard ball bearings in industrial applications provides significant advantages. These bearings enhance machine performance and increase operational efficiency. According to industry reports, machinery that employs high-quality ball bearings can achieve up to 30% longer service life compared to those that do not. This makes them critical in sectors like manufacturing and automotive.

Their design minimizes friction. This leads to reduced energy consumption. A recent study highlighted that adopting superior bearings can save companies up to 10% on energy costs. However, not all ball bearings are created equal. Factors such as material quality and lubrication play a major role in performance. Some industries still overlook these aspects, leading to preventable failures and downtime.

Moreover, standard ball bearings are adaptable. They cater to various operational environments, from high-speed applications to extreme temperatures. Some businesses find the variations overwhelming. The lack of understanding about the appropriate bearing for specific tasks can lead to inefficiencies. Inadequate selection is a common pitfall. Data shows that poor choices can result in up to 20% increased maintenance costs. This emphasizes the need for proper knowledge when selecting bearings for industrial use.

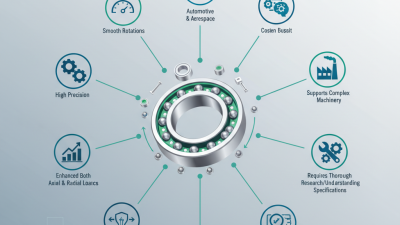

The chart above illustrates the different types of standard ball bearings commonly used in industrial applications in 2026. Each type serves specific functions and is utilized in various machinery, showcasing their importance in ensuring smooth operation and longevity of equipment.

When selecting ball bearings for industrial applications, performance ratings are crucial. These ratings help users understand the operational capabilities and limitations of various types. Essential factors include load capacity, speed rating, and friction characteristics.

For example, deep groove ball bearings can handle both radial and axial loads effectively. This versatility makes them popular in many machines.

Specifications often differ among bearing types. This variation can affect overall equipment efficiency. Considering the material construction is vital too.

Steel bearings may offer durability, while ceramic options can provide lower friction. However, the choice isn't always straightforward. Some users face challenges when evaluating each option effectively.

Regular maintenance keeps ball bearings functioning correctly. Over time, lubrication can degrade, affecting performance. Users should regularly check for signs of wear or noise. Assessing these aspects can prevent equipment failure. Yet, even the best-rated bearings may not perform as expected if not monitored. Understanding the full picture helps in making informed decisions.

The future of ball bearing technology in industrial applications looks promising. Manufacturers are keen on integrating advanced materials. These materials can enhance durability and performance. Lightweight composites are becoming popular. They offer higher resistance to wear and tear. However, they also pose challenges in production processes.

Another trend is the use of smart technology. Sensors embedded in bearings can monitor conditions in real time. This allows for predictive maintenance and minimizes downtime. On the flip side, these systems require a robust data analysis strategy. Many companies struggle to interpret this information effectively.

Sustainability is becoming a crucial factor too. Businesses are exploring eco-friendly manufacturing practices. This shift can lead to a significant reduction in waste. Yet, transitioning to greener solutions can be costly. Companies must weigh the benefits against their budget. Emerging trends point to a more efficient future, but adaptation remains a challenge.