In the realm of mechanical engineering and manufacturing, steel ball bearings serve as pivotal components that significantly influence the performance and longevity of machinery. According to recent industry reports, the global market for ball bearings is projected to grow at a CAGR of 6.8% from 2021 to 2026, fueled by the increasing demand in automotive, aerospace, and industrial machinery sectors. Steel ball bearings, known for their strength and durability, are essential for reducing friction in rotating applications, thereby enhancing efficiency and extending the lifespan of equipment.

The material properties of steel, including its high load-bearing capacity and resistance to wear, make steel ball bearings an ideal choice for high-performance applications. Data show that the right selection of ball bearings can lead to improved operational efficiency by 30% or more, a substantial saving for industries reliant on precision engineering. As such, the importance of choosing high-quality steel ball bearings cannot be underestimated; they are instrumental in maintaining optimal performance across various mechanical systems. This article aims to highlight the top 10 steel ball bearings that exemplify superior performance and durability, ensuring that businesses can make informed decisions in selecting the best components for their applications.

Steel ball bearings are crucial components in various applications, impacting overall performance and longevity. Several factors significantly influence their effectiveness, including material quality, lubrication, and load capacity. According to a report by the American Bearings Manufacturers Association, high-quality steel, such as through-hardened and case-hardened alloys, can enhance durability by up to 40% compared to lower-grade materials. This improvement is essential in demanding environments where wear and tear are prevalent.

Another critical factor is lubrication, which plays a significant role in reducing friction and heat generation. A study published in the Journal of Engineering Tribology indicates that proper lubrication can extend bearing life by 50%, as it minimizes metal-to-metal contact and subsequent degradation. It's essential to choose the right type of lubricant, as different applications may require greases or oils with specific properties to optimize performance. Additionally, the load capacity of steel ball bearings determines their suitability for various applications; bearings designed for higher loads can often withstand stress better, leading to enhanced longevity and reliability in critical systems.

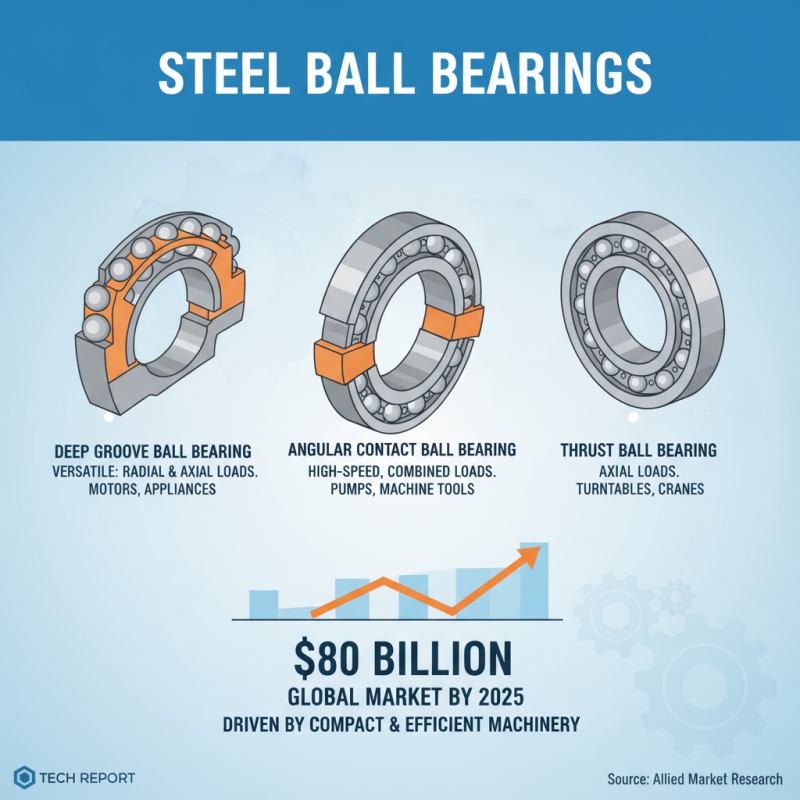

Steel ball bearings are critical components in various mechanical systems, providing efficiency and reducing friction between moving parts. There are several types of steel ball bearings, each tailored for specific applications. The most common types include deep groove ball bearings, angular contact ball bearings, and thrust ball bearings. Deep groove ball bearings are versatile and can handle both radial and axial loads, making them ideal for electric motors and household appliances. According to a report by Allied Market Research, the global ball bearings market is expected to reach $80 billion by 2025, driven by the increasing demand for compact and efficient machinery.

Angular contact ball bearings, on the other hand, are designed to accommodate higher speeds and axial loads, making them suitable for high-performance applications such as aerospace and automotive industries. Their design allows for the optimization of load distribution, enhancing the durability of the bearing under challenging conditions. Additionally, thrust ball bearings are specialized for axial load applications and are commonly employed in gearboxes and automotive transmissions. Research from Technavio indicates that the demand for thrust bearings is rising, reflecting the growing automotive sector and advancements in machinery engineering.

Selecting the appropriate type of steel ball bearing is crucial for achieving optimal performance and longevity in equipment. Each type offers unique advantages that can enhance reliability in specific applications, demonstrating the importance of understanding the functional requirements of a system before making a choice. As industries continue to evolve, the technology behind steel ball bearings is also advancing, ensuring that they meet the demands of modern machinery and applications efficiently.

The material composition of steel ball bearings is crucial for their performance and longevity. Typically made from high-carbon chromium steel, these bearings possess excellent hardness and wear resistance, owing to their carbon content which enhances strength and durability. The alloy is often treated with heat to achieve an optimal balance between toughness and hardness. Additionally, some manufacturers may incorporate materials such as stainless steel or specialized alloys to provide corrosion resistance and improve performance in specific environments, like those exposed to moisture or chemicals.

The manufacturing methods of steel ball bearings also play a vital role in determining their quality and reliability. Most commonly, the production process involves precision forging, grinding, and polishing. Precision forging helps in shaping the raw material into the desired forms with minimal waste, while grinding ensures that the surfaces of the balls are smooth and uniform. This meticulous process minimizes friction and enhances the overall efficiency of the bearings. To further optimize performance, advanced methods like heat treatment and surface hardening are employed, adding to the bearings’ longevity by enhancing their resistance to fatigue and wear under varying operational loads.

To ensure the longevity of steel ball bearings, proper maintenance is crucial. Regular cleaning is one of the key practices; contaminants such as dust, dirt, and water can accumulate over time and cause premature wear. Cleaning can be achieved by using a suitable solvent or detergent designed for removing debris without damaging the bearing surfaces. After cleaning, it is essential to dry the bearings thoroughly to prevent rust or corrosion, particularly in environments with high humidity.

Lubrication is another vital aspect of bearing maintenance. Selecting the appropriate type of lubricant—whether it's grease or oil—depends on the specific application and operational conditions. Proper lubrication reduces friction and heat, two primary factors that can lead to bearing failure. It's important to regularly check the lubrication levels and reapply as necessary. Additionally, monitoring operating temperatures and noise levels can provide insights into the condition of the bearings, allowing for timely interventions before serious issues arise. Regular inspections and adherence to manufacturer guidelines play a significant role in extending the performance and longevity of steel ball bearings.

When evaluating steel ball bearings, it is essential to conduct a comparative analysis of various leading brands to identify those that deliver optimal performance and longevity. Key performance indicators often include load capacity, rotational speed, friction coefficients, and temperature tolerance. Brands utilize different manufacturing techniques and materials, which can significantly affect the durability and efficiency of their bearings. Understanding these differences helps users select the most appropriate bearing for their specific applications.

Another aspect to consider in the analysis is the quality control measures implemented by manufacturers. Consistent quality assurance practices can lead to fewer failures and a longer operational lifespan. Moreover, lubrication methods and design innovations can enhance performance, affecting maintenance requirements and operational costs over time. Consumers should assess these factors comprehensively to make informed decisions that align with their operational demands and enhance the overall performance of their machinery.

| Model | Load Capacity (lbs) | Speed Rating (RPM) | Material | Price ($) |

|---|---|---|---|---|

| Model A | 500 | 10,000 | Chrome Steel | 15 |

| Model B | 600 | 12,000 | Stainless Steel | 20 |

| Model C | 550 | 15,000 | Chrome Steel | 18 |

| Model D | 650 | 11,000 | Carbon Steel | 22 |

| Model E | 700 | 9,000 | Stainless Steel | 25 |

| Model F | 720 | 14,000 | Chrome Steel | 28 |

| Model G | 680 | 8,500 | Carbon Steel | 30 |

| Model H | 590 | 13,000 | Stainless Steel | 32 |

| Model I | 640 | 17,000 | Chrome Steel | 35 |

| Model J | 710 | 16,000 | Carbon Steel | 38 |