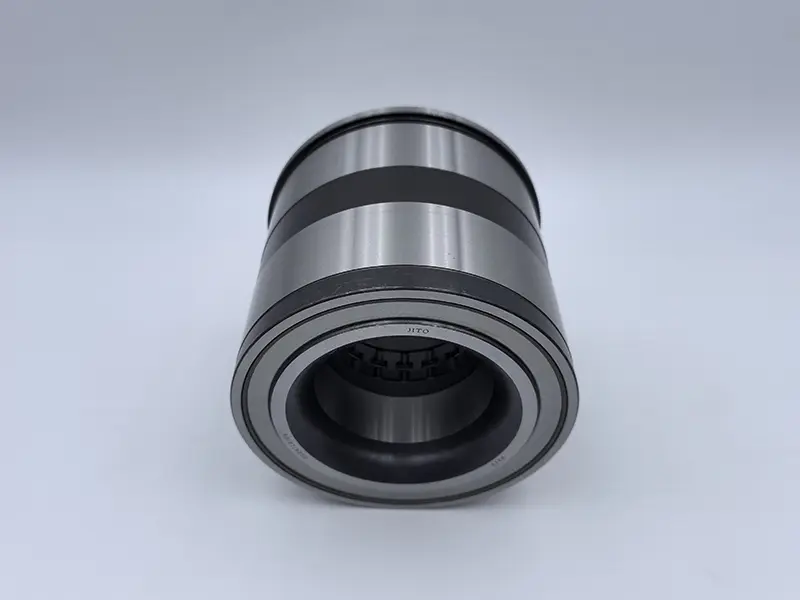

Double Roller Bearings: Boost Performance with High-Quality Solutions

As a veteran in the machinery parts industry, I recognize the importance of sourcing dependable components such as the Double Roller Bearing. Engineered to endure high radial loads with remarkable precision, these bearings are ideal for a wide range of manufacturing applications. At Liaocheng Jingnai Machinery Parts Co., Ltd., we take pride in providing high-quality Double Roller Bearings that surpass industry standards. Whether aimed at enhancing machinery performance or boosting efficiency, our expertly crafted bearings deliver exceptional results. With extensive experience, our team is dedicated to offering reliable products and excellent customer service tailored to your specific requirements. Let’s find the ideal Double Roller Bearing to enhance your operations today!Tips & Tricks for Double Roller Bearing Service Backed by Expertise Where Innovation Meets 2025

When it comes to ensuring the longevity and efficiency of double roller bearings, a strategic service approach backed by expertise is imperative. These components are engineered for high performance, but their effectiveness hinges on proper maintenance and service practices. To achieve optimal results, it’s vital to implement a routine inspection protocol and familiarize yourself with common wear indicators. Regularly monitoring operational conditions — such as temperature, vibration, and lubrication levels — will help identify potential issues before they escalate into costly failures. Innovative techniques in bearing service are continuously evolving. Adopting advanced diagnostic tools, such as vibration analysis and ultrasound testing, allows procurement specialists to gain deeper insights into bearing health. Consequently, businesses can make informed decisions regarding maintenance schedules and replacement cycles, enhancing productivity and minimizing downtime. As we approach 2025, blending innovation with best practices in bearing service is more critical than ever. The commitment to stringent quality control throughout the production process ensures that every bearing meets high standards, thus facilitating smoother operations. By embracing these tips and tricks, global buyers can secure reliable performance from their double roller bearings, driving their enterprises towards sustained success.

Tips & Tricks for Double Roller Bearing Service Backed by Expertise Where Innovation Meets 2025

| Tip | Description | Frequency | Expert Recommendation |

|---|---|---|---|

| Regular Inspection | Inspect bearings for signs of wear, overheating, or contamination. | Monthly | Utilize advanced monitoring tools for precision. |

| Proper Lubrication | Ensure bearings are lubricated according to manufacturer specifications. | Every 3 months | Consider synthetic lubricants for extended life. |

| Vibration Analysis | Monitor vibration levels to predict bearing failure. | Every 6 months | Implement real-time monitoring systems. |

| Alignment Checks | Check that roller bearings are properly aligned to avoid premature wear. | Quarterly | Use laser alignment tools for accuracy. |

| Clean Environment | Keep the working area free of dust and debris. | Continuous | Implement a regular cleaning schedule. |

Simple Ways To Double Roller Bearing For the Current Year Market Leader

A

Ava Martinez

Fantastic experience! The product is durable and the after-sales support was incredibly professional.

24 May 2025

E

Ethan Brown

Superb quality! The staff helped me promptly and were very knowledgeable about the product.

12 June 2025

J

James Taylor

Quality is unmatched! I’m grateful for the friendly and professional customer service experience.

17 June 2025

E

Evelyn Johnson

Very pleased with my purchase! The after-sales service was exceptional.

30 May 2025

N

Nathan Green

An impressive buy! After-sales support was prompt and highly effective.

29 June 2025

J

Joseph Lewis

I am very pleased with both the item and the service I received. Highly professional!

23 June 2025