Essential Guide to Greasing Wheel Bearings for Best Performance and Longevity

Greasing Wheel Bearings is vital for the smooth operation and longevity of machinery. Quality parts make a significant impact on maintenance and performance. Our tailored greasing solutions meet various application needs, ensuring reliability even under heavy loads and harsh conditions. Choosing Liaocheng Jingnai Machinery Parts Co., Ltd. means investing in premium grease and bearings that help reduce downtime and maintenance costs. Enhance your machinery's efficiency with our specialized greasing wheel bearings, ensuring dependable and smooth operation for the future.Step-by-Step Guide To Greasing Wheel Bearings Your End-to-End Solution Supplier

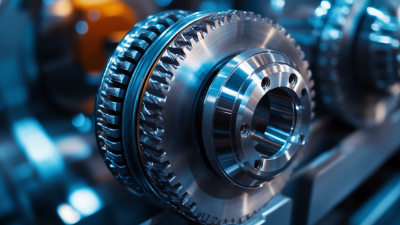

Maintaining the performance of wheel bearings is crucial for the longevity and efficiency of all types of vehicles. Greasing wheel bearings is a straightforward process that can significantly enhance their functionality, reduce noise, and prevent premature wear. In this step-by-step guide, we walk you through the essential steps, whether you are a seasoned mechanic or a DIY enthusiast. First, gather the necessary tools and materials: high-quality grease, a bearing packer (or a simple hand method), and a clean work surface. Start by removing the wheel and brake components to access The Bearings. Carefully clean the bearing surfaces with a solvent to eliminate old grease and debris. Inspect the bearings for any signs of damage such as pitting or discoloration; if found, it's best to replace them instead of greasing. Next, apply new grease to the bearings. If using a bearing packer, insert the bearing and pump until grease flows from the top. If using the hand method, scoop grease into the palm of your hand and pack it into the bearing until it overflows. Complete the process by reassembling the wheel components, ensuring everything is tightened to the manufacturer's specifications. Regular maintenance of wheel bearings not only extends their life but also contributes to overall vehicle safety, making it an essential task for every vehicle owner.

Step-by-Step Guide To Greasing Wheel Bearings Your End-to-End Solution Supplier

| Step | Description | Tools Required | Estimated Time |

|---|---|---|---|

| 1 | Remove the wheel to access the bearings. | Jack, lug wrench | 15 minutes |

| 2 | Take out the dust cover and retaining ring. | Flathead screwdriver, pliers | 10 minutes |

| 3 | Remove the Wheel Bearing Assembly. | Bearing puller | 20 minutes |

| 4 | Clean the existing grease from the bearings. | Degreaser, cloth | 15 minutes |

| 5 | Apply fresh grease to the bearings. | Grease gun, grease | 10 minutes |

| 6 | Reassemble the wheel bearing and reinstall on the wheel. | Impact wrench, torque wrench | 20 minutes |

| 7 | Reattach the wheel and lower the vehicle. | Jack, lug wrench | 15 minutes |

Practical Strategies for Greasing Wheel Bearings Manufacturers You Can Rely On Factory-Direct Excellence

M

Michael Thompson

The product quality is outstanding! It exceeded my expectations and the customer service was incredibly responsive.

09 June 2025

O

Olivia Nguyen

I love this product! The attention to detail in the service team was outstanding.

25 June 2025

M

Matthew Perez

An exemplary product! I was really impressed with the service provided by the team.

03 July 2025

L

Lily Jackson

Absolutely love this! I felt well-supported by the customer service staff.

23 June 2025

E

Ella Young

The experience has been great! The product quality really shines through.

29 May 2025

M

Maya Martinez

Impressed with both the quality and the service! Truly a positive experience all around.

29 June 2025