Heavy Duty Roller Bearings: Enhanced Reliability and Long-Lasting Performance

When superior performance and durability are essential for industrial machinery, Heavy Duty Roller Bearings offer the ideal solution. Engineered to handle extreme loads and harsh conditions, these bearings ensure longevity and reliable operation. As a business purchaser, the hassle-free installation and maintenance of these components make a significant difference. Liaocheng Jingnai Machinery Parts Co., Ltd. provides a broad selection, catering to diverse needs in construction, mining, and manufacturing environments. The importance of choosing the right parts is paramount, which is why our quality assurance stands out. With competitive pricing and exceptional service, investing in Heavy Duty Roller Bearings translates into enhanced efficiency and minimized downtime for your operations. Trust in quality to keep your machinery performing at its best.How To Heavy Duty Roller Bearings Delivers Unmatched Quality Service

When it comes to industrial applications, the importance of high-quality roller bearings cannot be overstated. Heavy-duty roller bearings are designed to withstand extreme loads and harsh operating conditions, ensuring reliability and longevity in machinery. One of the hallmarks of these bearings is their precision engineering, which directly impacts performance metrics such as wear resistance, operational efficiency, and thermal stability. By integrating advanced research and development with state-of-the-art manufacturing processes, these bearings offer unmatched quality and durability, making them a top choice for global procurement managers seeking trustworthy components for their operations. What sets top-tier heavy-duty roller bearings apart is the meticulous attention to detail throughout the entire production process. Each stage, from raw material selection to final assembly, is carefully monitored and controlled to meet stringent quality standards. This commitment ensures that The Bearing's structural integrity is maintained, reducing the risk of failures that could lead to costly downtimes. Additionally, the technological innovations embedded in these products enable them to perform effectively in diverse environments, adapting seamlessly to various applications across industries such as construction, mining, and manufacturing. For procurement managers looking to optimize their supply chain, investing in heavy-duty roller bearings not only guarantees exceptional operational performance but also translates into significant cost savings over time. The reliability of these bearings minimizes maintenance needs and extends the lifespan of equipment, contributing to a more efficient and productive operation overall. Engaging with modern manufacturing specialists in this field can pave the way for a partnership that drives innovation, enhances product quality, and meets the ever-evolving demands of global markets.

How To Heavy Duty Roller Bearings Delivers Unmatched Quality Service

| Bearing Type | Load Capacity (kN) | Material | Temperature Range (°C) | Lifespan (hours) |

|---|---|---|---|---|

| Spherical Roller Bearing | 150 | Chrome Steel | -30 to 120 | 40,000 |

| Cylindrical Roller Bearing | 200 | Stainless Steel | -40 to 150 | 50,000 |

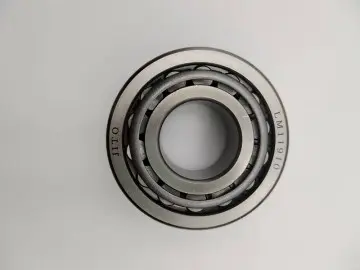

| Tapered Roller Bearing | 250 | Alloy Steel | -20 to 130 | 60,000 |

| Needle Roller Bearing | 100 | Chromium Steel | -30 to 120 | 30,000 |

| Thin Section Bearing | 75 | Bearing Steel | -20 to 100 | 20,000 |

Key Methods For Heavy Duty Roller Bearings For the Current Year Supplier

O

Oliver Wilson

Great product quality! I appreciate the thorough follow-up from the service team; they are very dedicated.

23 June 2025

S

Scarlett Robinson

I couldn’t be happier! They provide not just a quality product but also exceptional service.

11 May 2025

H

Hazel Wilson

So pleased with my purchase! Their diligence and professionalism are commendable.

25 May 2025

N

Nathan Green

An impressive buy! After-sales support was prompt and highly effective.

29 June 2025

H

Harper Lewis

Loved this product! Their customer support was prompt and attentive.

28 June 2025

G

Gabriel Harris

Impeccable quality! The professionalism of the service personnel was notable.

16 May 2025