Hub and Bearing Assembly: Quality Insights for Enhanced Performance

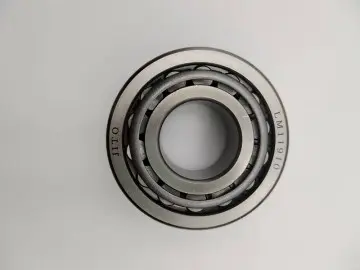

When reliable performance is essential, our Hub And Bearing Assembly is engineered for heavy-duty machinery applications. Built with rugged materials and precise engineering, this assembly promises durability and top-notch functionality, suitable for various industrial environments. It enhances equipment efficiency, whether for heavy lifting or high-speed tasks, providing the stability needed for optimal operations. The installation process is straightforward, minimizing downtime and increasing productivity. At Liaocheng Jingnai Machinery Parts Co., Ltd., our commitment to excellence ensures that our Hub And Bearing Assembly meets and often surpasses industry standards, instilling confidence in your investment. For more information on how we can meet your needs, feel free to reach out.Tips & Tricks for Hub And Bearing Assembly Your End-to-End Solution Guarantees Peak Performance

When it comes to optimizing the performance of mechanical systems, proper hub and bearing assembly is critical. Ensuring precision in this process can significantly enhance the efficiency and longevity of your equipment. Here are some essential tips and tricks to guide you through an effective assembly process. First, start with a clean workspace. Contaminants like dust and debris can compromise the integrity of the assembly, leading to premature wear and failure. Don’t overlook the importance of selecting high-quality bearing components; they are the backbone of your system's performance. Ensure that all parts are compatible and suited for your specific application to avoid any future complications. Additionally, pay attention to the assembly method. Utilize proper tools and techniques to achieve the correct torque specifications and achieve a tight fit. Regularly monitor and adjust the alignment during assembly. This attention to detail ensures that your end-to-end solution operates at peak performance, ultimately reducing downtime and maintenance costs while prolonging the lifespan of your machinery. Implementing these best practices will not only optimize your assembly process but also lead to enhanced operational efficiency.

Tips & Tricks for Hub And Bearing Assembly Your End-to-End Solution Guarantees Peak Performance

| Tip No. | Tip | Description | Expected Outcome |

|---|---|---|---|

| 1 | Clean Components | Ensure all parts are free of debris and contaminants before assembly. | Reduces friction and wear. |

| 2 | Proper Lubrication | Use appropriate lubricant for bearings and hubs to ensure smooth operation. | Enhances longevity and efficiency. |

| 3 | Torque Settings | Follow manufacturer’s specifications for torque settings on fasteners. | Prevents loosening or damage to components. |

| 4 | Alignment Check | Ensure all parts are aligned correctly during assembly. | Minimizes wear and ensures optimal performance. |

| 5 | Inspect Regularly | Conduct regular inspections and maintenance on the assembly. | Identifies potential issues before they escalate. |

The Ultimate Guide to Hub And Bearing Assembly Where Service Meets Innovation Industry Leaders

L

Liam Scott

Impressive experience! The service crew was skilled and very friendly.

22 June 2025

A

Anthony Hill

Wonderful service and product! The support staff was exceptionally professional.

18 June 2025

A

Alexander Lewis

Excellent experience! The product quality is up there, and the team is super polite.

11 May 2025

L

Liam Harris

Very pleased with the overall experience! The support team really knows their jobs.

30 May 2025

I

Isaac Garcia

Truly fantastic quality! The customer service was both friendly and professional.

29 June 2025

M

Mason Wilson

An excellent product! The service team was very responsive to my needs.

30 June 2025