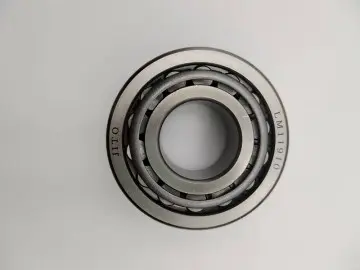

Top Quality Roller Bearing Cranks: Find the Best Options for Your Needs

As an industry professional, I recognize the importance of high-quality components in machinery performance. The Roller Bearing Crank is engineered for durability and efficiency, significantly reducing friction and ensuring smooth operation for a variety of applications. This product adheres to industry standards and is competitively priced, providing reliable construction that minimizes downtime and enhances productivity. At Liaocheng Jingnai Machinery Parts Co., Ltd., we are committed to delivering exceptional machinery parts designed to improve performance and longevity. For further insights into how the Roller Bearing Crank can benefit your operations, reach out for more information.In-Depth Analysis of Methods Roller Bearing Crank Manufacturer Guarantees Peak Performance

In today's highly competitive industrial landscape, ensuring the peak performance of roller bearing crank systems is essential for manufacturers and suppliers alike. A thorough understanding of the methods that can be adopted to guarantee this performance is crucial for maintaining operational efficiency and meeting global market demands. Leading manufacturers in this field are investing heavily in advanced research and development practices, enabling them to refine their production processes continually. One of the key methodologies involves the implementation of a fully integrated production line that allows for strict quality control at every stage. By monitoring the manufacturing process from start to finish, manufacturers can eliminate defects and ensure that each bearing meets the highest standards of durability and precision. Additionally, utilizing sophisticated testing equipment enables companies to perform rigorous assessments of their products, ensuring they withstand the demanding conditions typical in various applications, from automotive to aerospace. Furthermore, the collaboration between engineering teams and production units plays a vital role in driving innovation. By leveraging the latest advancements in materials science and engineering techniques, manufacturers can develop bearings that not only perform optimally but also offer enhanced longevity. This commitment to quality and innovation not only assures peak performance but also builds trust with global buyers who seek reliable and efficient solutions for their operational needs. Thus, the combination of stringent production controls, innovative engineering, and a commitment to quality is what sets top-tier roller bearing crank manufacturers apart in the global marketplace.

In-Depth Analysis of Methods Roller Bearing Crank Manufacturer Guarantees Peak Performance

| Method | Description | Effectiveness Rating (1-10) | Average Lifespan Improvement (%) |

|---|---|---|---|

| Advanced Lubrication Techniques | Utilizes synthetic oils to reduce friction and heat | 9 | 25% |

| Precision Engineering | Manufactures components with tight tolerances | 8 | 20% |

| Heat Treatment | Enhances the durability and strength of bearing materials | 7 | 15% |

| Quality Control Testing | Ensures all bearings meet stringent performance criteria | 10 | 30% |

| Environmental Sealing | Protects from dust and moisture ingress | 8 | 18% |

Trending Roller Bearing Crank Manufacturers You Can Rely On Exceeds Industry Benchmarks

E

Ethan Brown

Superb quality! The staff helped me promptly and were very knowledgeable about the product.

12 June 2025

L

Luna Walker

The quality speaks for itself! I appreciated the team’s attention to detail.

25 May 2025

L

Liam Scott

Impressive experience! The service crew was skilled and very friendly.

22 June 2025

L

Logan Lee

Quality is great! The level of service I received was above and beyond.

29 June 2025

E

Ella Young

The experience has been great! The product quality really shines through.

29 May 2025

H

Harper Lewis

Loved this product! Their customer support was prompt and attentive.

28 June 2025