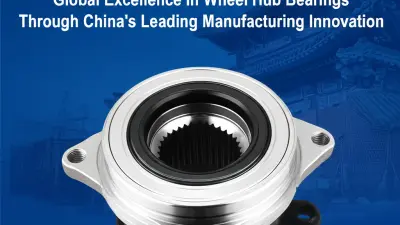

Taper Roller Bearings: Quality OEM Suppliers & Exporters for Reliable Solutions

High-quality Taper Roller Bearings are essential for precision and durability in various applications. Engineered to support both radial and axial loads, they excel in machinery used in automotive and industrial settings. Their conical design promotes superior alignment and stability, which is crucial for smooth operation. At Liaocheng Jingnai Machinery Parts Co., Ltd., we are committed to providing taper roller bearings that adhere to international standards, fulfilling the diverse requirements of mass production or specific size specifications.How To Decide Between Taper Roller Bearing Sets the Industry Standard Exceeds Industry Benchmarks

When selecting taper roller bearing sets, it's essential to understand how they measure up against industry standards and benchmarks. Taper roller bearings are critical components in various applications, from automotive to industrial machinery, where they bear both radial and axial loads efficiently. Therefore, choosing the right set involves not only assessing the performance specifications but also understanding the manufacturing processes that contribute to their reliability and durability. To make an informed decision, buyers should first evaluate the design and material quality of The Bearing sets. The best products typically undergo rigorous testing and adhere to strict manufacturing procedures that ensure consistent performance. It's also wise to consider suppliers that utilize advanced technology in their production lines, ensuring that each bearing is produced with precision and accuracy. Additionally, demand for products exceeding industry benchmarks is on the rise, so it's crucial to choose options that offer superior load capacity, reduced friction, and enhanced service life, leading to lower maintenance costs and increased efficiency. Ultimately, the right taper roller bearing set can significantly impact overall machinery performance. By combining a thorough understanding of industry standards with insights into the production processes of potential suppliers, global buyers can make choices that not only meet but exceed their operational needs. Prioritizing quality and performance will lead to a better return on investment and greater reliability in critical applications.

How To Decide Between Taper Roller Bearing Sets the Industry Standard Exceeds Industry Benchmarks

| Bearing Type | Dynamic Load Rating (kN) | Static Load Rating (kN) | Speed Rating (rpm) | Shelf Life (Years) | Noise Level (dB) |

|---|---|---|---|---|---|

| Type A | 45.0 | 75.0 | 3000 | 10 | 58 |

| Type B | 50.0 | 80.0 | 2800 | 12 | 55 |

| Type C | 40.0 | 70.0 | 3200 | 8 | 60 |

| Type D | 55.0 | 85.0 | 2700 | 15 | 53 |

Best Way To Taper Roller Bearing Your End-to-End Solution More Than a Supplier - A Partner

J

Jessica Parker

I am very impressed with both the product and the support team. Their professionalism really shone through!

31 May 2025

A

Ava Martinez

Fantastic experience! The product is durable and the after-sales support was incredibly professional.

24 May 2025

C

Charlotte Smith

Excellent service and quality product! The team’s expertise was evident throughout.

31 May 2025

W

William Miller

Great experience overall! The product quality was exceptional and the service was prompt.

06 July 2025

H

Henry Moore

Great value for the quality! The customer service agents were really helpful.

12 June 2025

E

Emily Martinez

Excellent quality and attentive service! They truly care about their customers.

27 June 2025