Thrust Bearings: OEM Solutions from Trusted Exporter & Manufacturer for Your Needs

At Liaocheng Jingnai Machinery Parts Co., Ltd., we specialize in high-performance thrust bearings designed for exceptional quality and durability, crucial for your machinery's efficiency. Our advanced manufacturing facilities utilize the latest technology to ensure that our products consistently meet strict industry standards. We understand the value of strong partnerships, so we prioritize building trust with our factory collaborators to guarantee timely deliveries and tailored solutions. Our thrust bearings excel in applications requiring effective axial load handling, promoting enhanced performance and longevity. Choose us for reliable thrust bearings crafted for your specific industry needs, and enhance your productivity with our unmatched expertise and commitment to quality.

Insider Tips For Thrust Bearing Use in 2025 Manufacturers You Can Rely On

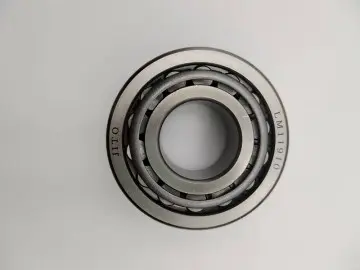

As manufacturers prepare for 2025, understanding the intricacies of thrust bearing use is crucial for both performance and longevity. Thrust bearings play a vital role in various applications, from automotive to industrial machinery, handling axial loads efficiently. When selecting thrust bearings, it's essential to consider factors such as material, load capacity, and operating conditions. Advanced materials like ceramics and high-performance alloys offer improved resistance to wear and temperature fluctuations, enhancing the durability of these components. In addition to material selection, leveraging the latest production technologies can significantly impact the performance of thrust bearings. Manufacturers are increasingly adopting automated processes and precision machining to ensure the highest quality standards. This integration of technology not only improves accuracy but also reduces production times, allowing for quicker turnaround and adaptability in meeting market demands. For global purchasers, establishing relationships with reliable manufacturers is key. Look for companies that emphasize rigorous quality control throughout their production processes. By choosing suppliers who prioritize innovation and consistent performance, businesses can ensure they are equipped with the best thrust bearings, ultimately leading to enhanced machinery efficiency and reduced operational costs in the long run.

Insider Tips For Thrust Bearing Use in 2025 Manufacturers You Can Rely On

| Dimension | Material | Load Capacity (N) | Max Speed (RPM) | Temperature Range (°C) | Lubrication Type |

|---|---|---|---|---|---|

| 100 mm x 200 mm | Steel | 5000 | 3000 | -30 to 120 | Grease |

| 80 mm x 160 mm | Brass | 4000 | 2500 | -20 to 110 | Oil |

| 120 mm x 240 mm | Aluminum | 6000 | 3500 | -40 to 130 | Grease |

| 90 mm x 180 mm | Plastic | 3000 | 2000 | -10 to 90 | Oil |

The Clear Choice of Thrust Bearing Use Service Custom Solutions,

M

Michael Martinez

This product is a game-changer! I appreciated the professional guidance from the support team.

30 June 2025

A

Avery Hall

Loved the product and the support team was very attentive to my questions!

11 June 2025

M

Matthew Perez

An exemplary product! I was really impressed with the service provided by the team.

03 July 2025

H

Hazel Wilson

So pleased with my purchase! Their diligence and professionalism are commendable.

25 May 2025

I

Isaac Baker

Excellent product quality and the support team’s expertise made all the difference!

24 June 2025

I

Isaac Garcia

Truly fantastic quality! The customer service was both friendly and professional.

29 June 2025